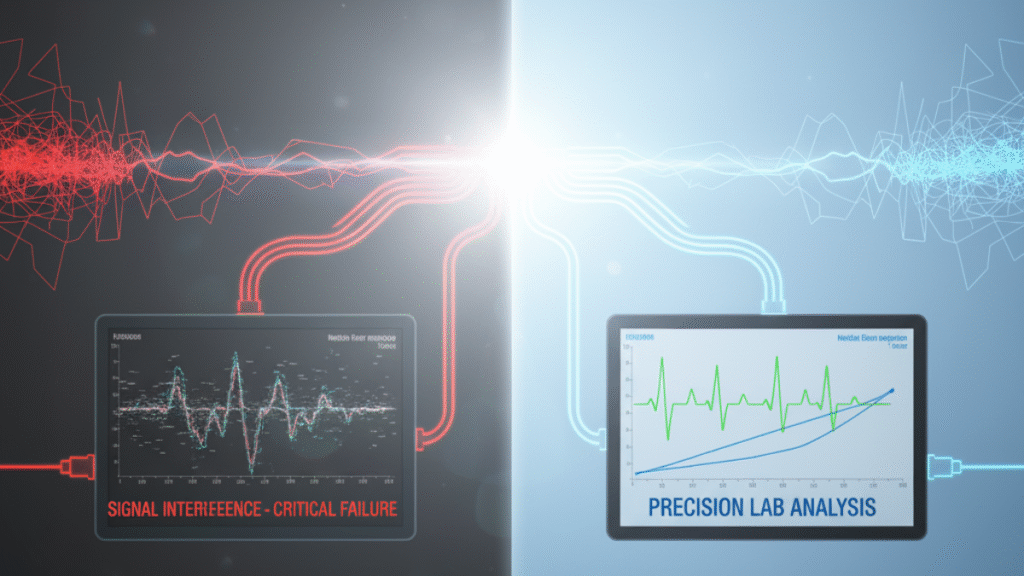

If you frequently come into contact with precision medical equipment, you may find that some devices like monitor and scanner,the ECG waveform on the monitor suddenly jitters, the values of the laboratory instruments occasionally drift, and stripes appear in the scanner image.

Clean power supply is the starting point of all precision signals

In the situation above, you may think that they are just some glitches and will disappear after restart, but the fact won’t lie. The situation is usually caused by high ripple power supplies instead of devices being broken.

Now you may know that a high quality low ripple medical power supply means a lot to precise medical equipment. You want your equipment run stably, your power adapter must be a “clean” one.

What is power ripple?

So what is power ripple? Ripple refers to the AC component or noise superimposed on the DC output. It always comes from residual ripple after AC rectification, high-frequency noise caused by the on/off of switching devices, and current fluctuations caused by load changes.

In simple terms, the DC (direct current) in the microscopic world is not a straight line but an undulating wave.

Why are low ripple power supplies crucial for precision equipment?

There are several reasons for precise medical equipment to choose a low ripple power supply, it’s not a “need”, it’s a “must”.

Here are the reasons:

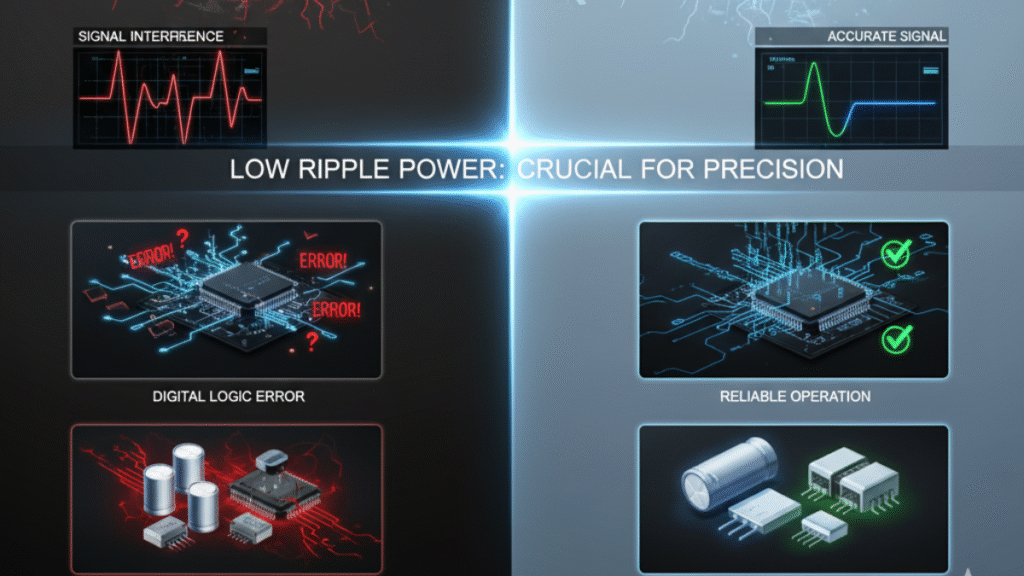

First, the signal’s precision depends on “clean” power.

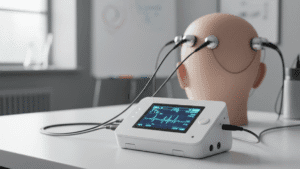

The signal in medical devices is weak and needs to be enlarged, for example, the electrocardiogram signals detected by medical monitoring equipment, the microvolt voltage difference collected by electrochemical analyzers, and the photosensitive current of imaging systems. These signals can’t be detected without enlarging and transforming.

The ripple is far stronger than the signals, so if there’s nothing to reduce it, ripple interference will mix into the signal channel and appear as noise, jitter, and waveform drift.

Second, with ripple digital circuit logic errors can occur.

Microprocessors, MCUs, and memory devices can experience momentary voltage fluctuations due to ripple interference, causing false triggering of logic or data errors.

And for medical devices, errors are not acceptable.

Third, high ripple will accelerate electric components aging.

When a power supply output has high voltage ripple, it means the voltage is not a stable DC voltage, but rather constantly fluctuates between high and low levels. For critical components like capacitors, inductors, and IC chips, this constantly fluctuating voltage acts like a fatigue test.

How to reduce ripple in power supply design?

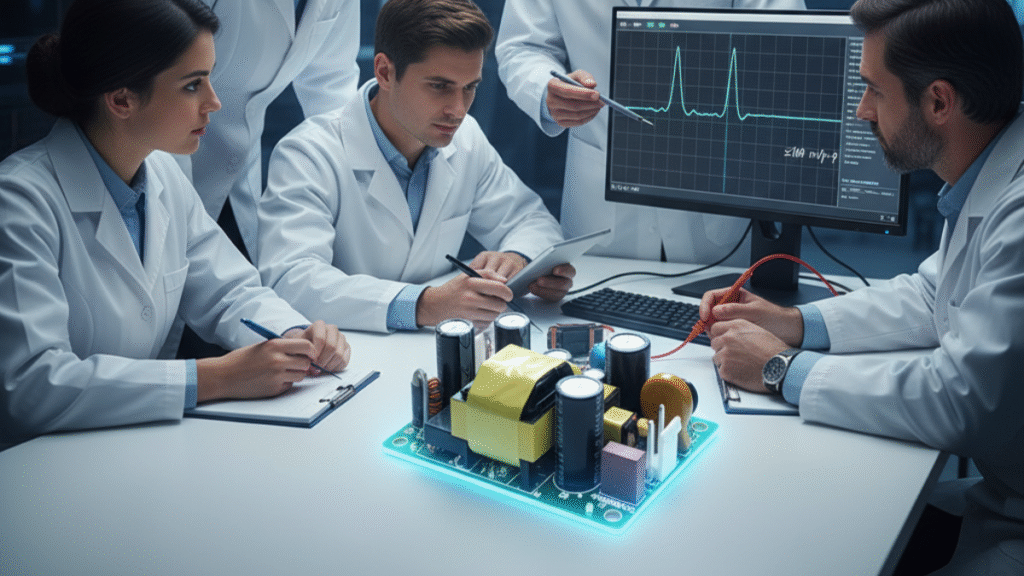

Ripple interference is already a history in Quankang, our engineers undertook many methods and finally solved the problem. They used multi-stage filtering (LC, π-type filtering) in circuit designing, optimising feedback loop stability to avoid oscillation.

The engineers figure out that the keys to achieving low ripple output lie in three key aspects:

Selecting low-ESR capacitors and low-loss magnetic core materials.

Optimizing the PCB layout to shorten high-frequency loops and strengthen the ground plane, and suppressing common-mode noise through metal shielding and single-point grounding.

Finally, use an oscilloscope to monitor the ripple peak to ensure that the medical power supply output is ≤100 mVp-p.

Conclusion

A good power supply is like a tranquil river, allowing all electronic signals to flow smoothly.

Choosing a high-quality adapter with low ripple isn’t just about ensuring your device turns on, but also ensuring it works accurately.

Contact us for power supply solutions with lower ripple and greater stability.