Medical beds can look simple, but their safety depends on something you rarely see — the power supply. A wrong power choice can silently damage performance or even patient safety.

Class 2 power supplies are ideal for medical beds because they limit output current, reduce shock risk, meet medical safety standards, and fit seamlessly into compact motor systems for safe and reliable operation.

A good power supply doesn’t just provide energy — it protects what matters most. For medical beds, this includes both the patient and the internal electronic systems. I’ve worked with enough equipment failures to know that cutting corners on power almost always leads to regrets. That’s why more manufacturers now start their design from the power module, not the motor.

How Does a Class 2 Rating Improve Bed Safety?

Power isn’t just about voltage. It’s about control. Uncontrolled current can cause overheating, sparks, or worse — silent damage to sensitive circuits.

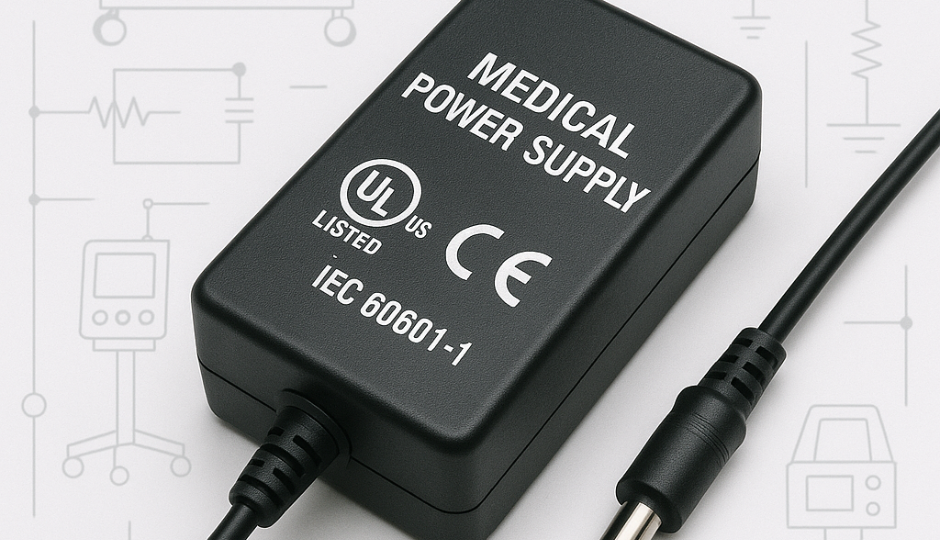

Class 2 power supplies meet UL 1310 standards, limiting energy output to safe levels, which protects both patients and caregivers in a medical environment.

What Makes Class 2 Different from Other Power Adapters?

When developing a new patient bed design, we often start by asking: how much power is truly necessary? Too much, and we add danger. Too little, and motion becomes unreliable. Class 2 hits that balance. It is restricted to 100VA or less, which prevents dangerous current levels even in fault conditions.

Take this example:

| Specification | Class 2 Power Supply | General-Purpose Adapter |

|---|---|---|

| Max Output Power | 100VA | >100VA |

| Shock Risk if Fault Occurs | Low | High |

| Required Isolation | Reinforced | Often Basic |

| Compliance Requirements | UL 1310, IEC 60601 | Often Lacks UL/IEC Certs |

| Typical Use Case | Medical beds, chairs | TVs, laptops, lighting |

In one hospital project, we replaced a general 24V adapter with a Class 2 certified one. The motor output became more stable, the heat reduced significantly, and we passed IEC 60601-1 testing in a single round, saving both cost and time.

How Does It Help with Motor Control and Bed Movement?

Medical beds include motors that raise the head, legs, or tilt the entire frame. These require precise voltage and steady current. But sudden surges — like when multiple motors engage — can cause delays or failures.

Class 2 power supplies regulate current flow and prevent spikes, allowing electric motors to operate smoothly and quietly without overheating.

Smooth Motion = Better Care

I remember one instance where a patient’s bed made a loud clicking noise every time it tilted up. It wasn’t a mechanical issue — it was an unstable power adapter struggling to deliver consistent output. Once we installed a Quankang 24V Class 2 unit with a regulated current cap, the issue disappeared.

This kind of stability makes it easier to:

- Avoid sudden stops or jerks during movement

- Reduce stress on motor windings

- Lower total energy draw for the system

- Extend bed service life with less maintenance

Here’s how current regulation improves experience:

| Feature | Without Class 2 Supply | With Class 2 Supply |

|---|---|---|

| Bed motion response time | Slow, inconsistent | Smooth, precise |

| Motor heat during use | High | Low |

| Risk of short circuit | Higher | Much lower |

| Compliance testing results | Often failed | Passed consistently |

Reliable motion isn’t just about mechanics — it’s about electrical consistency.

What Makes Class 2 Power Supplies Easy to Design Around?

Every millimeter matters in bed design. Manufacturers are under pressure to shrink electronics and simplify assembly. Bulky, enclosed adapters often don’t fit inside the motor compartment or bed frame.

Class 2 supplies often come in open frame or compact form factors, making them ideal for OEM integration into medical bed control systems.

OEM Designers Need Flexibility

One advantage I’ve found in Class 2 modules is their form factor. Open frame designs, in particular, can mount directly on the main PCB or inside slim control boxes under the bed. This reduces wiring complexity and lowers EMI risks.

Why this matters:

- Reduces power loss over long wires

- Less cooling is required due to low wattage

- Streamlined assembly and fewer connectors

- Fast certification when using pre-approved modules

In one project, switching from a plastic-enclosed supply to an open frame Class 2 unit freed up 20mm of vertical space — just enough to add a backup battery system.

How Does It Lower Compliance and Testing Costs?

Medical devices must meet international safety rules — not just for patient health, but also for insurance and legal reasons. Each extra component adds to the testing cost and time.

Class 2 supplies often come pre-certified for medical use, which speeds up product compliance and reduces the risk of rejection during final safety inspections.

Pre-Certification Is a Hidden Advantage

I’ve learned that using non-certified power modules often backfires. Even if the rest of the bed passes mechanical inspection, the power supply can block the whole product from entering the market.

With Class 2 units:

- IEC 60601-1 and UL 1310 are already covered

- The leakage current is within medical limits

- Isolation meets reinforced insulation requirements

This means less paperwork, faster audits, and better peace of mind. In fast-paced product cycles, that alone can make or break a launch deadline.

Conclusion

Class 2 power supplies protect patients, improve motor performance, simplify design, and speed up compliance, making them the best choice for today’s electric medical beds.