We all know that a medical-grade power adapter always has higher requests, which means better design, far more testing, and so many certifications, then a medical power adapter can be put into use.

Introduction

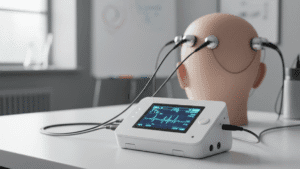

A medical-grade power adapter is a kind of power supply only used for medical devices, like an ultrasound scanner, a ventilator, or an electrocardiograph. These devices need stable power and very low leakage current; that’s not only the request of the devices, but also the necessity to save lives.

Design

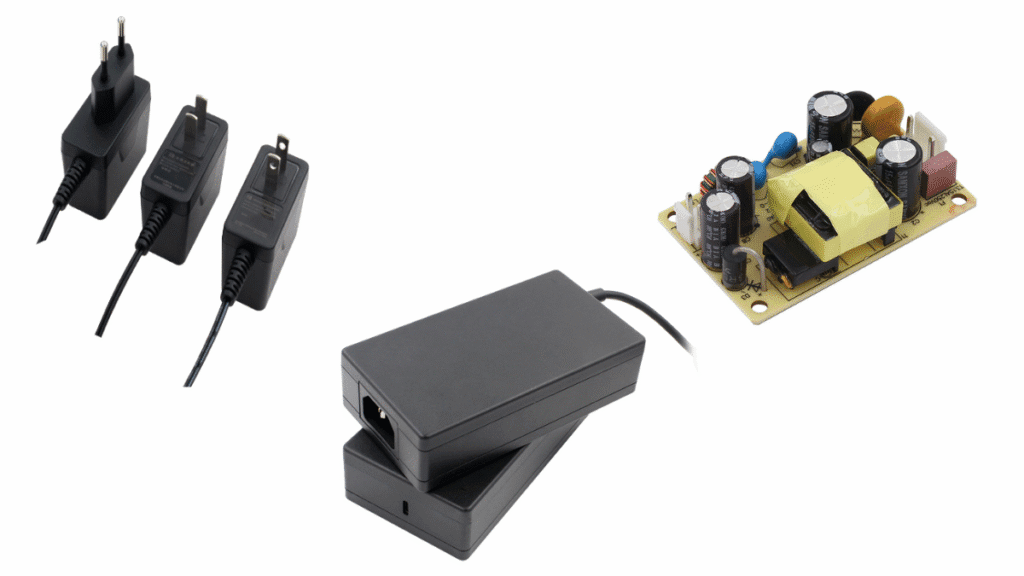

An outstanding medical-grade power supply needs to be designed very carefully; engineers should put safety and human protection in the first place instead of cost or power. And as for safety, first is reinforced insulation and isolation, engineers design clearance and creepage for adapters to prevent being penetrated by electric arc and stop current from discharging along the adapter surface.

What’s more, engineers use a series of methods to prevent electric shock to people who contact medical devices or power supplies.

Firstly, medical power adapters use a class II structure, which means that there are two layers of insulation in the adapters; even when the inner layer of insulation fails due to high temperature, the current will be blocked by the outer one.

Secondly, an isolation transformer is set up between the main circuit (connected to the 220V alternating current) and the secondary circuit (output to the equipment) to transmit energy through magnetic coupling, rather than direct connection of conductors, fundamentally reducing the risk of electric shock.

Testing

Many medical devices can’t afford mistakes and low quality in power supply, so medical-grade power supplies need to be tested many times before being put into use.

First is security and performance testing, including insulation withstand voltage test, ground continuity, leakage current, short circuit protection, and output voltage stability tests.

Second is the environment and aging test, to see how the adapters work in high and low temperatures, in wet or dusty space, after falling to the ground, and check the output voltage stability under full load.

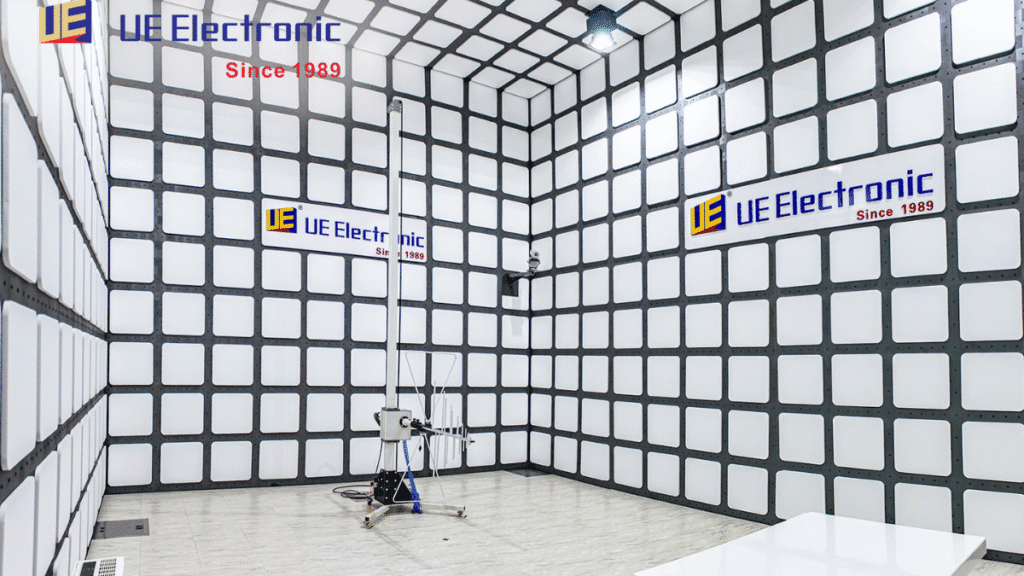

Finally is the EMC/EMI test, whose purpose is to ensure that the adapter will not generate electromagnetic interference and interfere with the normal operation of other devices. Only after an adapter passed all these tests, then it could be used by the medical devices. But if there is even one test that it didn’t pass, the adapter will be given upon and redesigned.

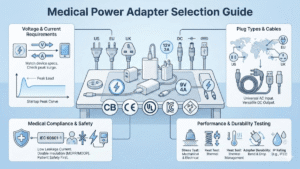

Certification

All I mentioned above will only happen in factories, but the certifications need a more professional and qualified certification body(CB). All medical power supplies must meet the certificate of IEC 60601-1; you can always see the UL(Underwriters Laboratories), CB(Conformité Européenne), CE(Certification Bodies Scheme), and TUV(Technischer Überwachungsverein) mark on the surface of a medical-grade power supply. And if you want to use adapters in different countries, the adapter should meet the specific certificates of the country, for example, UL in the USA, EN in Europe, PSE in Japan, and CCC in China. Obtaining certification means that product safety and consistency are recognized by international standards.

Put into use

When the adapters can meet all the requirements I mentioned, they can be put into use. But it doesn’t mean that they will not be changed in the future, the factory will undertake production consistency control, and take random inspections to ensure each batch of products is safe and stable. Pay attention to customers’ feedback(adapter’s temperature, failure rate, etc) and base on the feedback to improve the design and manufacturing process.

Conclusion

The ultimate value of medical-grade adapters lies in “stable protection of life“.It’s not a gimmick, but a strict system.

The birth of each “medical-grade adapter” is a comprehensive embodiment of safety, quality, and responsibility.