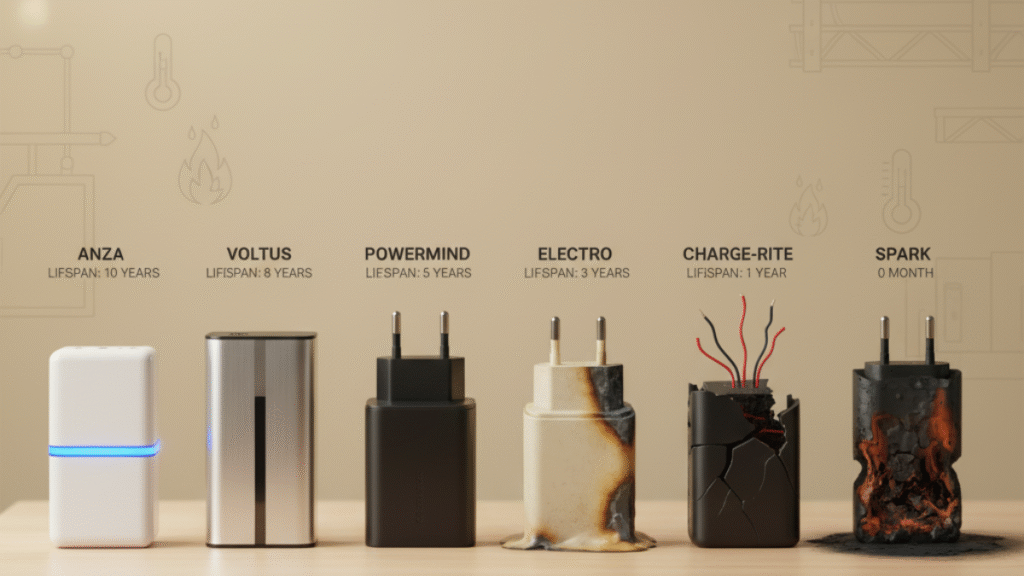

All electronic products have a lifespan, and so do power adapters. But the end of the adapter’s service life does not happen suddenly. An adapter often reaches the end of its service life due to the gradual aging of its internal electronic components, until it is replaced due to frequent heating and cannot work properly.

Different power adapter have different lifespan

I believe it is easy to understand,even the adapters with the same power ,their lifespan could be totally different.And that is because adapters with different brands have their natural gap of hardwares due to their cost,which means the materials are different.

However, the lifespan of an adapter is not solely determined by the materials used. More critical factors include the structural design and the operating environment. An adapter operating in a long-term high-temperature environment will significantly reduce its lifespan, but good design can slightly compensate for this. Let’s talk about the hardware first.

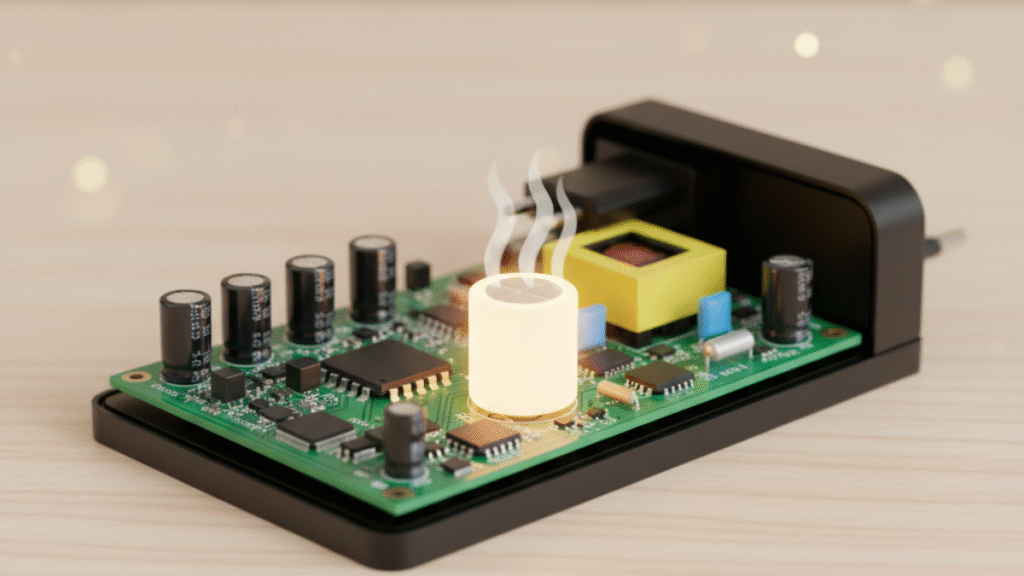

Component aging is the core of service life

A sophisticated power supply typically contains electrolytic capacitors, IC chips, transformers, rectifier diodes, and other components. If these components are like the boards that make up a barrel, the electrolytic capacitor is the shortest board. It is the most sensitive to temperature. The electrolyte within the capacitor evaporates or decomposes more rapidly as temperature rises, gradually degrading its dielectric properties and weakening the oxide film surrounding the electrolyte until it breaks down.

Thus, the quality of the electronic components in a power adapter directly determines its lifespan under normal circumstances. After all, water in a barrel leaks out through the shortest board. Therefore, high-quality adapter manufacturers like Quankang choose electrolytic capacitors from well-known brands to maximize the lifespan of this “shortest board.”

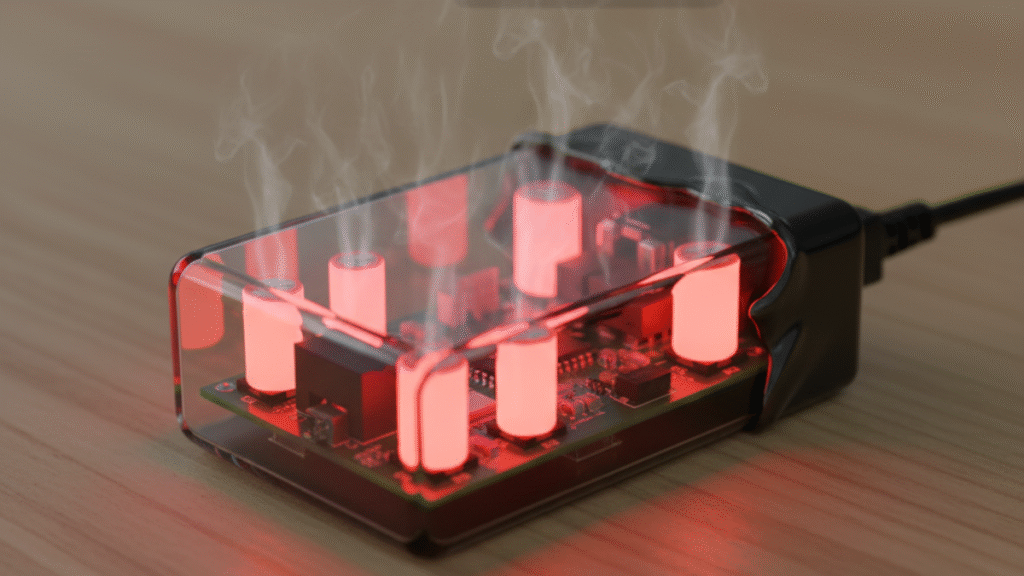

Temperature is the driving force behind accelerated adapter aging

As mentioned above, high temperatures accelerate the volatilization or decomposition of the electrolyte in electrolytic capacitors, which can also affect other parts of the adapter.

Poor-quality adapters often lack a good heat dissipation design, which can easily lead to excessive internal heat. Prolonged exposure to high temperatures can degrade the performance of IC chips and other semiconductor components, leading to PCB deformation, increased leakage current, and other consequences.

In addition to components, high temperatures can also affect the adapter’s casing. It’s important to note that, with the exception of some open-frame power adapters, the majority of adapter casings are made of engineering plastic with an inner insulating layer.High temperature will melt the insulation layer and engineering plastic housing,or even lead to a fire disaster.

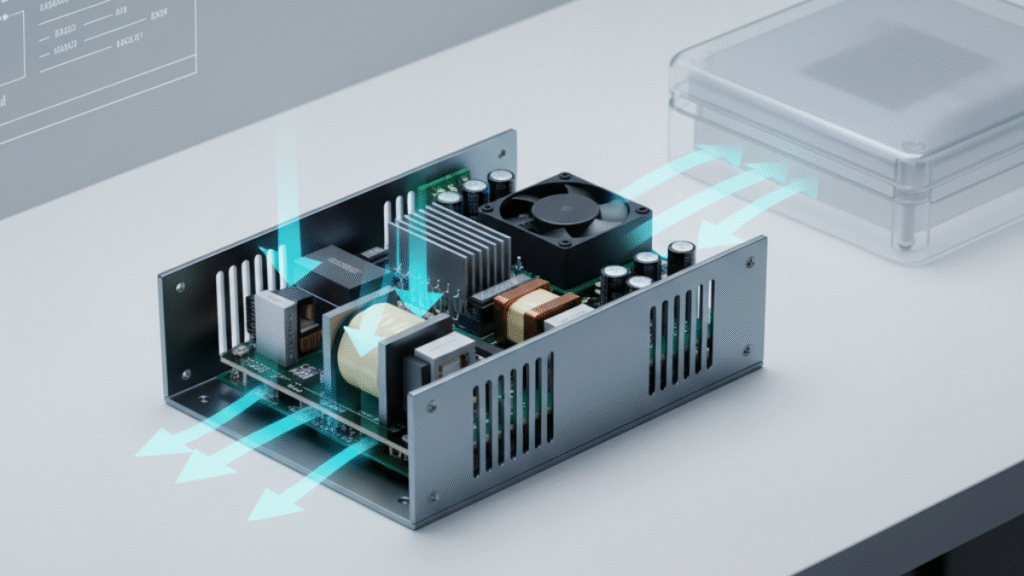

Heat dissipation design plays an important role in extending service life

As we know that temperature affects service life,then obviously heat dissipation design can help to have a longer use of power adapter.A high quality power adapter ,usually an open-frame power adapter, will be equipped with better heat conduction paths, such as metal casing, glue potting process, and air duct optimization.Some will also be equipped with a fan to ensure the stability under high load situation. If a power adapter is always working under a high load situation, the speed it ages will be far faster than normal use.High-quality power supplies often reserve a margin for rated power. For example, they may be marked as 100W but can run stably at 120W. This is a guarantee of lifespan.

The external usage environment is also important

Dust, humidity, and power grid fluctuations can all affect the lifespan of an adapter.Dust can block heat dissipation, while moisture can cause leakage or corrosion.In areas with unstable voltages, if the adapter lacks surge protection or voltage regulation, internal components can be damaged more quickly.Long-term operation in a high-temperature, closed environment will also significantly shorten its lifespan.

Conclusion: Lifespan is not accidental, it is designed

The lifespan of an adapter is determined by a combination of materials, design, protection, thermal management, and the operating environment.

For medical equipment, which demands extremely high stability, a reliable and long-lasting medical power adapter is particularly important.