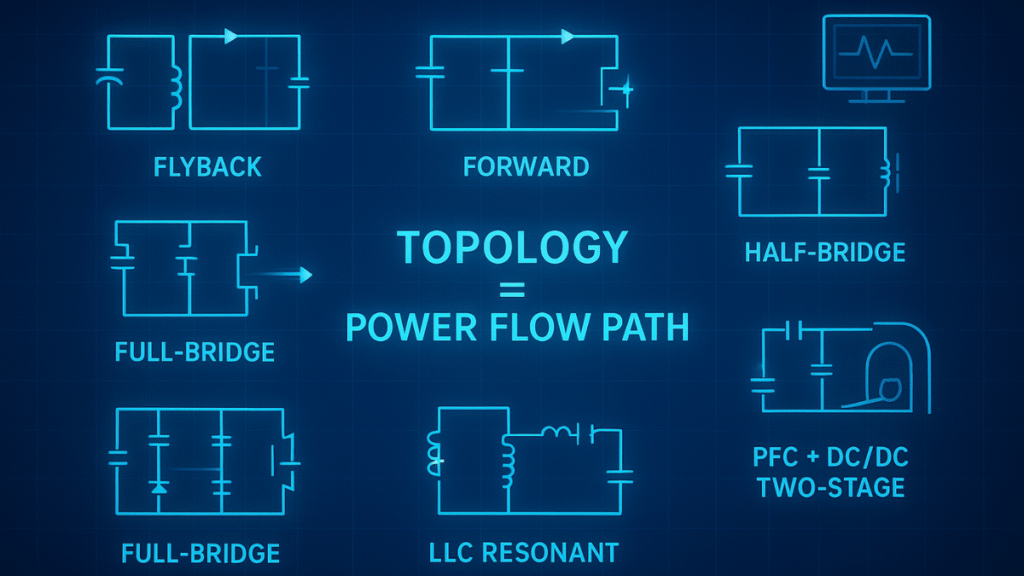

Topology is the soul of modern medical-grade power adapters; it determines how the energy is transformed and controlled. For example, two 60W power supplies, one can pass the medical-grade certification without issue, while the other overheats or produces noise. The difference often lies in the topology design.

What “Topology” really means in power adapter design

Topology is not just an abstract concept; as we mentioned before, it is the path for energy to flow, the core of a good quality adapter.

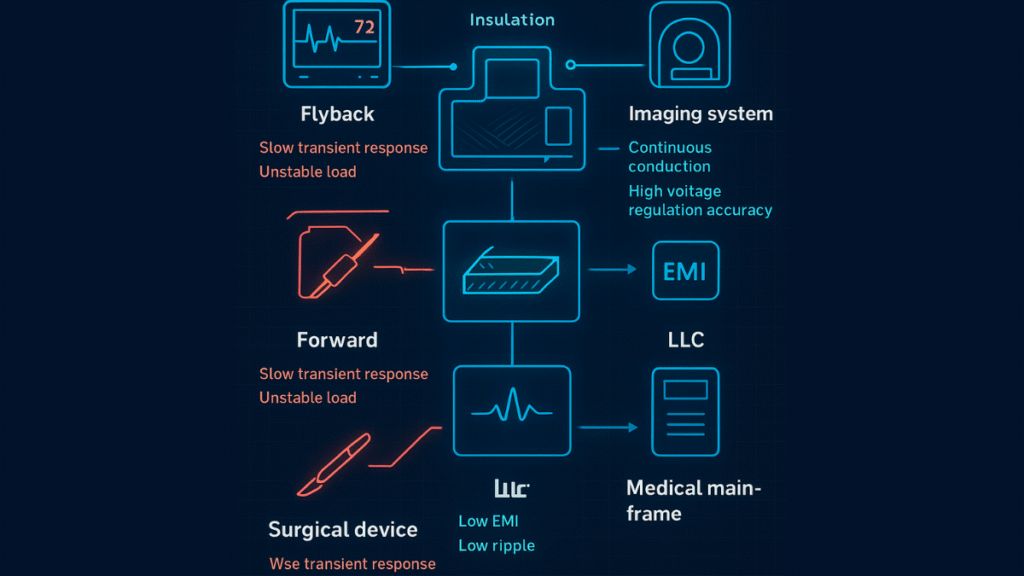

There are six main types of topology for medical power supply: Flyback, Forward, Half-Bridge, Full-Bridge, LLC resonance, and PFC + DC/DC two-stage structure.

Among them, Flyback is used for a wide power range (5–100W), simple structure, and low-cost adapters, as well as the vast majority of small and medium-sized medical adapters.

Forward is suitable for 100–250W, with higher efficiency than flyback, lower ripple, and is used in portable medical devices.

Half-Bridge can be used for 200–500W range adapters, which will have good stability and easy EMI control.

Full-Bridge is for high-power devices above 500W (such as medical lasers, electric beds).

LLC Resonant is known for High efficiency and low noise, commonly used in high-end medical mainframes or imaging systems.

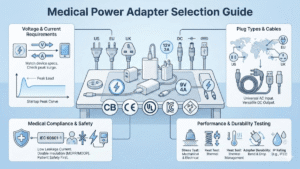

PFC(Power factor correction) + DC/DC Two-Stage Structure: PFC is added at the input, and LLC or Flyback is used at the output, meeting IEC 60601 requirements for efficiency and EMI.

In summary, Flyback dominates low-power medical adapters, while LLC and PFC+LLC dominate high-end or mainframe applications. Think of topology as the blueprint of how your adapter breathes power — quietly, efficiently, and safely.”

Why Medical Applications Need Specific Topologies

For a medical power supply, nothing is more important than leakage current limitation, insulation structure, and transient load response. And that’s why some topologies are naturally suited for patient-contact medical devices; take LLC as an example; this structure is known for low EMI and low ripple, which are needed by many medical devices.

Flyback converters have slow transient response and are prone to overshoot due to sudden load changes; forward, half-bridge, and full-bridge converters have continuous paths and faster response. Imaging equipment often uses this type of topology to prevent voltage sag.

Flyback converters have weak load stability, and their output varies greatly with the load; LLC and forward converters offer continuous conduction and high voltage regulation accuracy. Medical mainframes require voltage fluctuations within ±1%.

Quankang’s Approach to Medical Power Topology

At Quankang, we customize topology and component selection to balance power density, thermal control, and safety certification demands.

For low-power medical adapters, Quankang uses flyback and forward topology to save the cost and use the savings to upgrade hardware and to meet the IEC60601-1, CE, UL, along other certifications. For high power and high precision healthcare devices, we design their power supplies with PFC+DC/DC Two-Stage Structure, ensuring them having great performance, like far lower EMI, high efficiency up to 95%, extremely low leakage current, and mini size.

In Quankang, many configurations can be customized. Contact us to get your best-suited medical-grade power adapter.