A momentary flicker or glitch on a ventilator’s screen might seem minor — but it can compromise life-saving decisions in critical care environments.

Power adapters play a critical role in ensuring ventilator displays operate with consistent clarity and accuracy by delivering stable voltage and minimizing signal noise, crucial for real-time monitoring.

When medical staff depend on accurate visual data from ventilator displays, even the smallest signal instability can distort what they see or delay what they need to know. Ventilator displays aren’t just screens—they are lifelines. And behind them, the power adapter ensures consistent brightness, uninterrupted operation, and uncorrupted signals. Many manufacturers overlook this silent component, but in my experience, it’s often the difference between operational excellence and repeated field failures.

Why does unstable power cause ventilator display issues?

A ventilator’s screen needs more than just power — it needs uninterrupted, clean power. Power disruptions lead to more than blackouts; they can cause flickering, screen freezing, or incorrect display of vital signs.

Unstable voltage or noisy currents from low-grade adapters can cause the ventilator display to lag, distort readings, or lose calibration entirely, risking clinical decisions and patient safety.

Why display clarity depends on power stability

In many modern ventilators, the display is not just a basic LCD showing a few values. These are now high-resolution touchscreen panels, often integrated with patient records, alarms, and waveform analysis. These screens run sensitive electronics and require regulated DC power to operate correctly. Voltage fluctuations can reduce screen brightness, delay refresh rates, or create artifacts on waveforms. In my work with one client, a drop of just 0.3V in a 12V power rail caused their ventilator screen to dim and misread CO₂ levels — a costly recall followed.

Factors affecting display quality tied to the adapter:

| Parameter | Impact on Display |

|---|---|

| Voltage Ripple | Can cause pixel noise or waveform distortion |

| Load Regulation | Affects brightness and touch responsiveness |

| EMI (Electromagnetic Interference) | May interfere with signal integrity and display clarity |

| Transient Response | Slow response to sudden load change can cause flicker |

| Ground Isolation | Prevents signal feedback loops and ghost images |

How do power adapters ensure data accuracy?

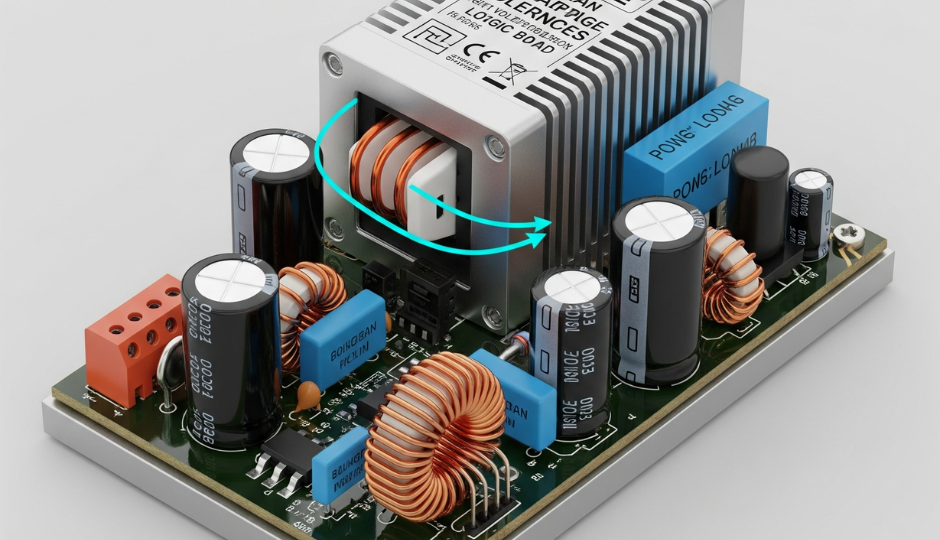

When clinicians depend on numbers on-screen to adjust oxygen levels or ventilation modes, any inaccuracy can be dangerous. That’s why power supply noise or fluctuation must be eliminated before it reaches the logic board.

Medical-grade power adapters use tight voltage tolerances, isolation barriers, and filtering components to protect the ventilator’s signal processing, ensuring accurate display of patient data.

What happens when signal noise enters the display logic?

Even small voltage spikes can corrupt the microcontroller’s ability to process sensor data. For example, a pulse oximetry module may report a saturation value of 96% instead of 91% if the analog signal gets distorted by power noise. I’ve seen firsthand how inconsistent power led a ventilator to trigger false alarms, adding stress to ICU staff and reducing trust in the equipment.

Adapter features that improve accuracy:

| Power Adapter Feature | Function |

|---|---|

| Low Noise Output | Preserves integrity of analog signals |

| Tight Load Regulation (<2%) | Prevents logic errors during display refresh |

| Certified Medical Isolation | Eliminates ground loops and external interference |

| Built-in PFC (Power Factor Correction) | Reduces harmonic distortion affecting sensitive systems |

What power adapter specs should ventilator manufacturers focus on?

It’s not just about meeting power requirements — it’s about optimizing for reliability under continuous operation. Ventilators often run 24/7 in high-stakes environments, so every component must be selected for durability and compliance.

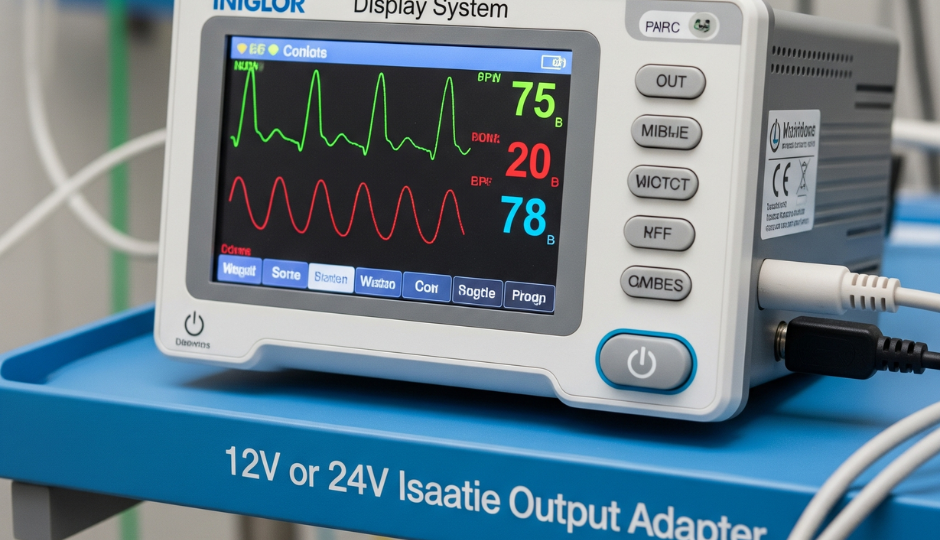

Ventilator display systems require 12V or 24V output adapters with low ripple noise (<50mVp-p), medical-grade isolation (2 x MOPP), and certifications like IEC 60601-1 to meet safety and performance expectations.

Consider these technical criteria:

| Specification | Recommended Value |

|---|---|

| Output Voltage | 12V / 24V DC (±5%) |

| Ripple & Noise | <50mVp-p (for clear signal) |

| Isolation Protection | 4000Vac (2 x MOPP, IEC 60601-1) |

| Efficiency Level | DOE Level VI or higher |

| Operating Temperature | 0°C to +60°C with full load |

| MTBF (Mean Time Between Failures) | >100,000 hours (at 25°C ambient) |

Many times, when working with product teams, I’ve had to argue for higher-end adapters despite cost concerns. But when the equipment’s reliability directly affects patient lives, the cost of failure is far higher than the premium on a certified power adapter.

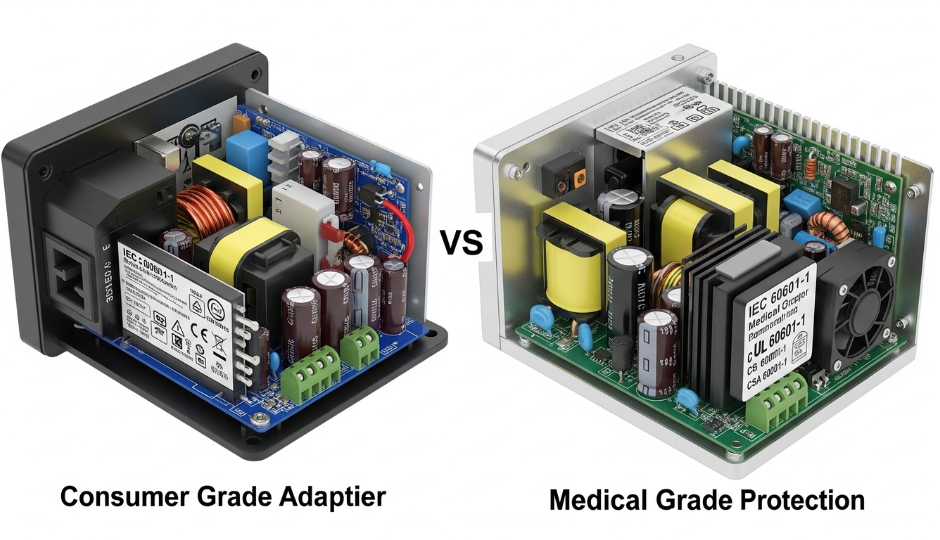

Are all power adapters suitable for ventilator displays?

Not at all. While consumer-grade adapters may look similar on the outside, their internal components, EMI shielding, and quality assurance processes differ significantly.

Only medical-grade power adapters with full certification, noise control, and thermal protection are suitable for ventilator displays operating in life-critical environments.

What happens when the wrong adapter is used?

I recall a client who sourced adapters from a low-cost supplier to reduce BOM costs. Within three months, nearly 17% of ventilator units reported flickering displays and false data alarms. Post-failure analysis revealed high EMI from unshielded transformers and unstable DC rails due to poor regulation. After switching to an IEC-certified adapter, the issue was eliminated.

Common pitfalls when selecting substandard adapters:

- Inconsistent voltage output is causing waveform lag

- No medical certification leading to compliance failures

- Inadequate thermal protection is causing the display shut down

- EMI radiation is interfering with touchscreen controls

- No surge protection leading to early component wear

Conclusion

Ventilator displays rely heavily on clean, stable power, and the power adapter is the unsung hero ensuring clarity and data precision every second.