I. Introduction

A desktop power supply is one of the most essential components in modern computing and electronic systems. Whether it is an internal ATX power supply that powers a traditional desktop PC, or an external switching power adapter that drives monitors, docking stations, medical instruments, or other consumer electronics, the reliability of the power source directly determines the stability of the entire device. A failing or unstable power supply may cause voltage drops, overheating, system crashes, data loss, or even permanent damage to connected equipment. For this reason, testing a desktop power supply is not only a professional requirement in laboratories and manufacturing plants, but also an important maintenance practice for technicians, engineers, and advanced users.

This article provides a comprehensive guide to testing desktop power supplies, covering the basics of understanding how they work, safety precautions, functional checks, voltage measurements, load and ripple testing, advanced performance analysis, troubleshooting, and real-world case studies. While the focus is broad enough to apply to both internal and external PSUs, special attention will be given to external switching power adapters, since these play a critical role in consumer and industrial devices today.

II. Understanding Desktop Power Supplies

To understand how to test a power supply, it is essential first to comprehend what it is and how it operates. A desktop power supply converts the alternating current (AC) from a wall outlet into direct current (DC) at specific voltages and currents suitable for electronic devices. Internal ATX power supplies inside PCs often provide multiple rails such as +12V, +5V, and +3.3V. In contrast, external switching power adapters usually output a single regulated voltage, such as 12V, 19V, or 24V, depending on the equipment.

The key parameters of a power supply include voltage output, current capacity, wattage, efficiency, and safety certifications. For instance, a typical desktop adapter may be rated at 12V/5A, which means it can deliver up to 60W of power. Efficiency determines how much input energy is converted into useful output; low-efficiency power supplies waste energy as heat. Certifications such as UL, CE, FCC, and IEC 60601 for medical power supplies ensure compliance with safety and performance standards.

Common issues found in desktop power supplies include overheating due to insufficient cooling, unstable voltage outputs, insufficient wattage leading to device underperformance, and connector problems that cause intermittent power loss. Testing is therefore the only reliable method to confirm whether the unit is performing within specifications.

III. Safety Precautions Before Testing

Testing desktop power supplies involves working with live electrical equipment. Improper handling can lead to electric shock, fire hazards, or damage to expensive electronics. Therefore, safety precautions must always come first.

Before starting, ensure that the workspace is dry, clean, and non-conductive. Using insulated gloves and tools minimizes the risk of accidental short-circuits. It is recommended to keep a fire extinguisher rated for electrical fires nearby when working with high-wattage PSUs.

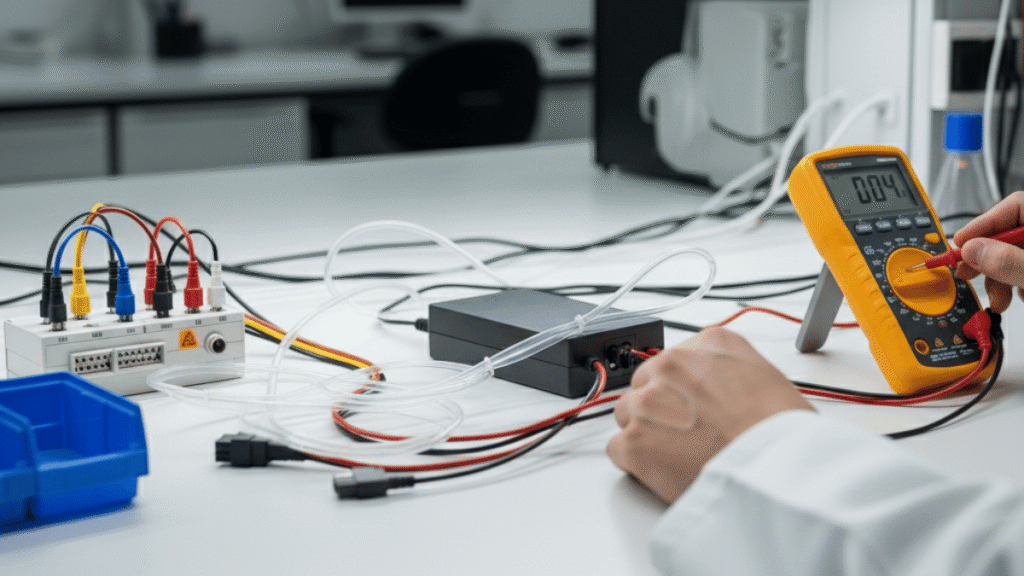

Several tools are typically required for testing: a digital multimeter for voltage and continuity checks, a PSU tester for ATX power supplies, an electronic load device for simulating real-world current draw, and an oscilloscope for analyzing ripple and noise. In professional environments, high-end test benches and automated testing machines may be used, but for most applications, the combination of a multimeter, load tester, and oscilloscope is sufficient.

IV. Basic Functional Testing

The first stage of testing is a simple functional check to determine whether the desktop power supply is operational. This begins with a visual inspection. Check whether the housing is intact, the cables are undamaged, and the connectors are not loose or corroded. Any visible damage is already a warning sign.

Next, verify that the label on the adapter or PSU matches the device’s requirements. For example, if a monitor requires 19V/3.5A, then using a 12V adapter would not only fail to power the device but could potentially cause permanent harm.

When powering on the adapter, look for status indicators such as LED lights. A steady green LED usually indicates that the unit is functioning. However, even if the indicator lights up, it does not guarantee that the output voltage is correct or stable. That is why further testing with instruments is mandatory.

V. Voltage Output Testing

The most fundamental test of a desktop power supply is measuring its voltage output using a digital multimeter. Connect the multimeter probes to the positive and negative output terminals of the adapter or PSU, and read the displayed voltage.

If the power supply is rated at 12V, the reading should ideally be between 11.4V and 12.6V, which represents the common ±5% tolerance allowed for DC adapters. Any result outside this range indicates a defective or poorly regulated power supply. Similarly, a 19V adapter should measure between 18.05V and 19.95V.

It is important to perform voltage measurements both under no-load conditions and while the power supply is connected to a device or load tester. Some power adapters may show a correct voltage without a load, but once connected to equipment, the voltage may drop significantly due to weak components. Recording these results over multiple tests provides a clearer picture of the unit’s stability.

VI. Load Testing

Voltage testing alone does not fully represent real-world performance. A power supply must be tested under load to simulate the conditions of actual use. This is where electronic load testers are essential.

To conduct a load test, connect the desktop power supply to a programmable load device and gradually increase the current draw to the rated maximum. For instance, a 12V/5A adapter should be tested at incremental steps such as 1A, 3A, and 5A. During each stage, record the voltage and monitor whether it remains within tolerance.

Another important observation during load testing is heat dissipation. High-quality switching adapters include thermal protection and efficient heat sinking, while low-quality units may overheat quickly, leading to shutdowns or safety risks. By maintaining the load for an extended period, one can evaluate the durability of the power supply.

VII. Ripple and Noise Testing

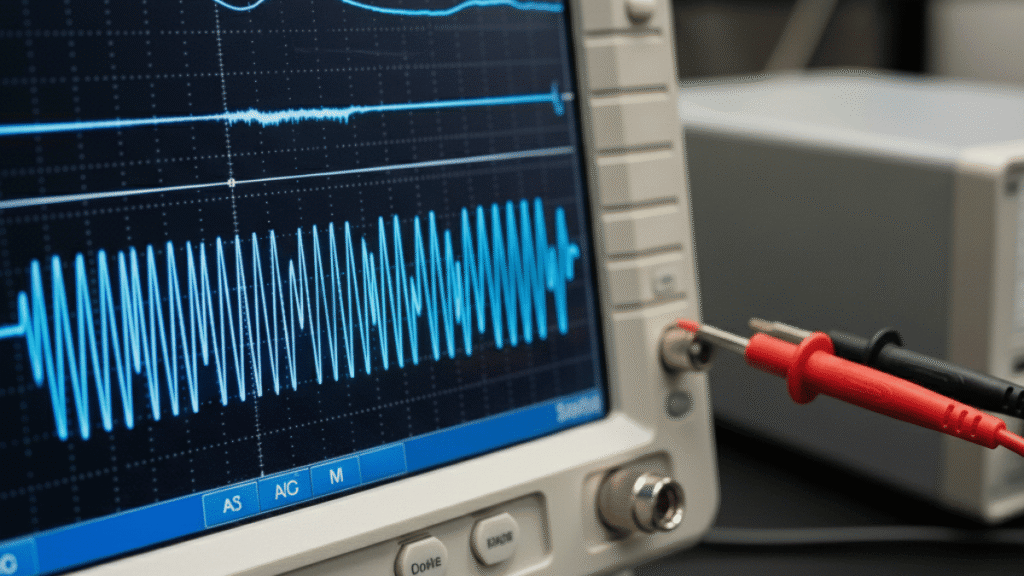

Ripple refers to the small AC voltage fluctuations superimposed on the DC output of a power supply. While a minor ripple is inevitable, an excessive ripple can cause instability in sensitive electronic equipment such as medical devices, audio systems, or high-performance computers.

Testing ripple requires an oscilloscope. Connect the oscilloscope probes to the output terminals of the adapter, ensuring proper grounding to avoid distortion. Observe the waveform on the screen. For most desktop adapters, acceptable ripple levels are below 120mV peak-to-peak for 12V rails.

If the measured ripple exceeds this threshold, it indicates poor filtering or degraded capacitors inside the power supply. Devices powered by such an adapter may experience noise interference, reduced lifespan, or random errors. High-quality adapters designed for professional and medical use typically demonstrate very low ripple levels, which is why ripple testing is a vital step in power supply evaluation.

VIII. Advanced Performance Testing

Beyond basic voltage and ripple checks, advanced testing ensures that the power supply performs well in demanding scenarios. Efficiency testing measures how much power is wasted during conversion. For example, if an adapter consumes 70W from the wall but only delivers 60W to the device, its efficiency is 85%. Efficiency not only affects electricity costs but also determines how much heat is generated.

Power Factor Correction (PFC) is another important metric, especially for higher-wattage power supplies. Active PFC ensures that the current draw from the AC line is smooth and reduces wasted energy.

Protection testing is equally critical. High-quality desktop power supplies include safeguards such as overcurrent protection, overvoltage protection, and short-circuit protection. To test these, engineers intentionally create fault conditions under controlled environments to verify whether the PSU shuts down safely instead of damaging connected devices. Burn-in testing, where the unit is operated continuously under heavy load for many hours, is also performed in manufacturing environments to ensure long-term reliability.

IX. Common Problems and Troubleshooting

Several problems are frequently encountered during power supply testing. If there is no output voltage at all, possible causes include blown fuses, failed internal components, or faulty connectors. Overheating may result from dust buildup, blocked ventilation, or degraded capacitors.

Voltage drops under load often indicate that the adapter cannot deliver its rated current, which may happen with counterfeit or low-quality products. Intermittent shutdowns may be caused by inadequate overcurrent protection or thermal instability. Physical damage, such as bent pins or frayed cables, should never be ignored, as they present fire hazards.

Knowing how to identify these issues allows technicians to determine whether the power supply can be repaired, recalibrated, or must be replaced entirely.

X. Testing Desktop Power Supply in Different Scenarios

Desktop power supplies are used in a wide range of environments, and testing methods may vary accordingly. For home or office PCs, the main concern is stable 12V and 5V rails for CPUs, GPUs, and storage devices. For industrial applications, reliability under continuous operation is more important than peak performance.

Medical devices impose even stricter requirements. Power adapters used in medical equipment must comply with IEC 60601 standards, ensuring ultra-low leakage current, minimal ripple, and robust insulation. Testing in this context is highly rigorous and usually conducted in certified laboratories.

Consumer electronics such as docking stations, monitors, and external drives rely heavily on external adapters. In such cases, the testing focus is on ensuring that the adapter delivers correct voltage and sufficient current, as well as verifying compatibility with the connected devices.

XI. Professional vs. DIY Testing

Not all testing requires a professional laboratory. Basic voltage measurements and simple functional checks can be conducted at home using a multimeter. However, ripple testing, efficiency analysis, and safety certification must be carried out with specialized equipment by trained professionals.

DIY testing is sufficient for determining whether an adapter is still usable. But when it comes to mass production, medical equipment, or high-value electronics, professional certification is non-negotiable. International standards such as IEC, UL, CE, and FCC exist to ensure that power supplies meet safety and electromagnetic compatibility requirements. Manufacturers bear the responsibility of conducting these tests before releasing products to the market.

XII. Case Study: Testing an External Switching Power Adapter

To illustrate the process, consider testing a 12V/5A external switching power adapter. The first step is to visually inspect the housing and cables. Once confirmed intact, a multimeter test shows the no-load voltage at 12.15V.

Next, the adapter is connected to an electronic load, gradually increased to 5A. The voltage remains stable at 12.05V, indicating strong regulation. Thermal testing shows the housing temperature rising moderately but within safe limits. An oscilloscope test reveals a ripple of 80mV peak-to-peak, which is acceptable for most applications.

Finally, after a 6-hour burn-in test at 80% load, the adapter maintains stable performance without shutdowns. This demonstrates that the adapter meets its specifications and is suitable for long-term deployment.

XIII. Best Practices for Ensuring Long-Term Power Supply Health

Regular inspection and testing help extend the lifespan of desktop power supplies. Ensuring adequate ventilation prevents overheating, while using the correct wattage for each device avoids overloading. Users should avoid cheap counterfeit adapters, as these often lack essential safety features.

Certified adapters from reputable manufacturers not only deliver reliable performance but also protect the connected equipment from electrical hazards. For industries such as healthcare and automation, investing in high-quality external switching power adapters is not just a matter of convenience but a necessity for safety and compliance.

XIV. Conclusion

Testing a desktop power supply is a systematic process that ranges from basic visual inspection to advanced laboratory evaluation. By following structured methods—checking voltage output, performing load testing, analyzing ripple and noise, and verifying protective functions—users and professionals can ensure that their power supplies are safe, reliable, and efficient.

In a world where electronic devices are indispensable, the power supply remains the hidden foundation of stability. For manufacturers, rigorous testing demonstrates product quality and compliance. For users, it provides peace of mind that their systems will function reliably. Whether you are a technician, an engineer, or a business relying on external switching power adapters, testing your desktop power supply is an investment in performance, safety, and long-term durability.