Introduction

When people think of a thermometer, they typically envision a straightforward device that displays the current temperature. The question, “How does a thermometer work?” seems straightforward. Yet the answer is far more complex than it appears, especially when we expand the scope from traditional mercury thermometers to modern digital and infrared devices. Today, thermometers are used in a wide range of fields—from basic home health monitoring to highly demanding clinical diagnostics and industrial manufacturing.

At the heart of accurate measurement lies not only the sensing technology but also the stability of the power source. A reliable power adapter plays a crucial role in ensuring precision, consistency, and safety in modern thermometers. Without a stable supply of electricity, digital sensors cannot function properly, amplifiers produce noise, and microcontrollers generate errors that compromise results.

This article explores how thermometers work, beginning with traditional models and progressing to advanced electronic and infrared types. We will examine how power adapters contribute to their operation, accuracy, and reliability. By connecting the evolution of thermometers with the role of power supply technology, we can better understand why the power adapter is a silent yet essential partner in precision measurement.

Traditional Thermometer Principles (Mercury and Alcohol Thermometers)

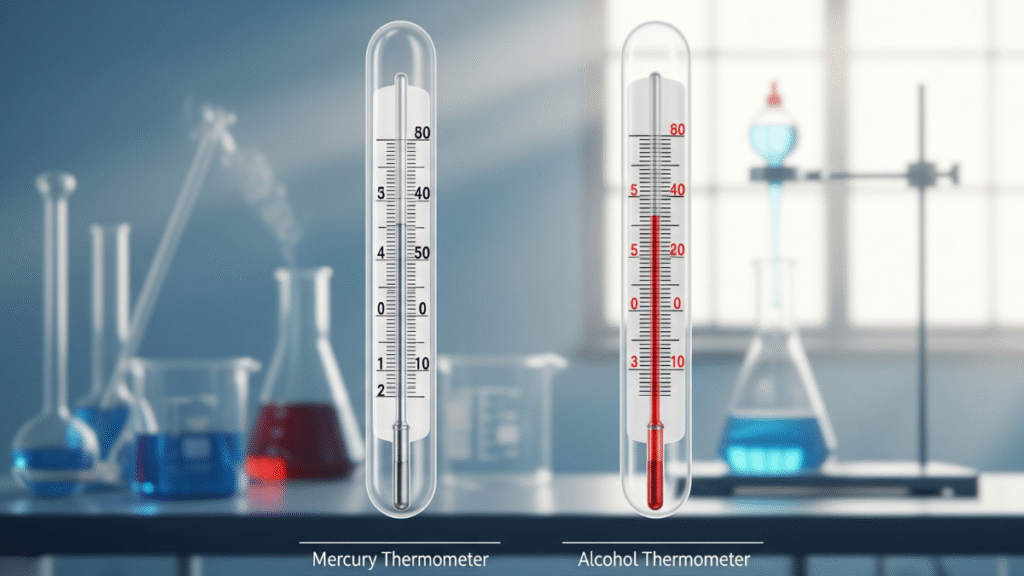

Long before electronics and sensors entered the field, thermometers relied on the simple principle of thermal expansion. Mercury and alcohol thermometers are the two most iconic examples of traditional thermometers.

Mercury Thermometers

A mercury thermometer consists of a glass capillary tube with a small reservoir of mercury at one end. As the temperature rises, mercury expands and pushes further up the tube. The scale on the tube correlates the height of the mercury column to temperature.

Mercury has several desirable properties for thermometry:

- It expands uniformly with temperature.

- It remains liquid over a wide temperature range (from -39 °C to 356 °C).

- It does not wet the glass walls, which ensures consistent readings.

These qualities make mercury thermometers highly accurate, reliable, and suitable for scientific applications.

Alcohol Thermometers

Alcohol thermometers use colored ethanol or other alcohols. Alcohol expands more than mercury, making it easier to observe temperature changes. They also function in lower temperatures, even below -100 °C, where mercury would freeze.

Alcohol thermometers are safer to handle because alcohol is less toxic than mercury. Their visibility is enhanced by adding dye, making them easy to read in low light.

Advantages and Disadvantages

- Advantages of Mercury Thermometers: High accuracy, stable, and long lifespan.

- Disadvantages of Mercury Thermometers: Toxicity, risk of breakage, limited to positive temperatures above -39 °C.

- Advantages of Alcohol Thermometers: Wide temperature range, safe, inexpensive.

- Disadvantages of Alcohol Thermometers: Less precise, evaporative losses, and scale distortion over time.

Limitations of Traditional Thermometers

Traditional thermometers do not require electricity. This simplicity is both their strength and their weakness. While they are robust, they cannot meet the demands of modern healthcare or industrial applications. Reading them requires human interpretation, response time is slow, and integration into digital systems is impossible. In an age where accuracy must be combined with speed, automation, and data storage, traditional thermometers have clear limitations.

Digital Thermometer Principles (Thermistors, Thermocouples, Electronic Sensors)

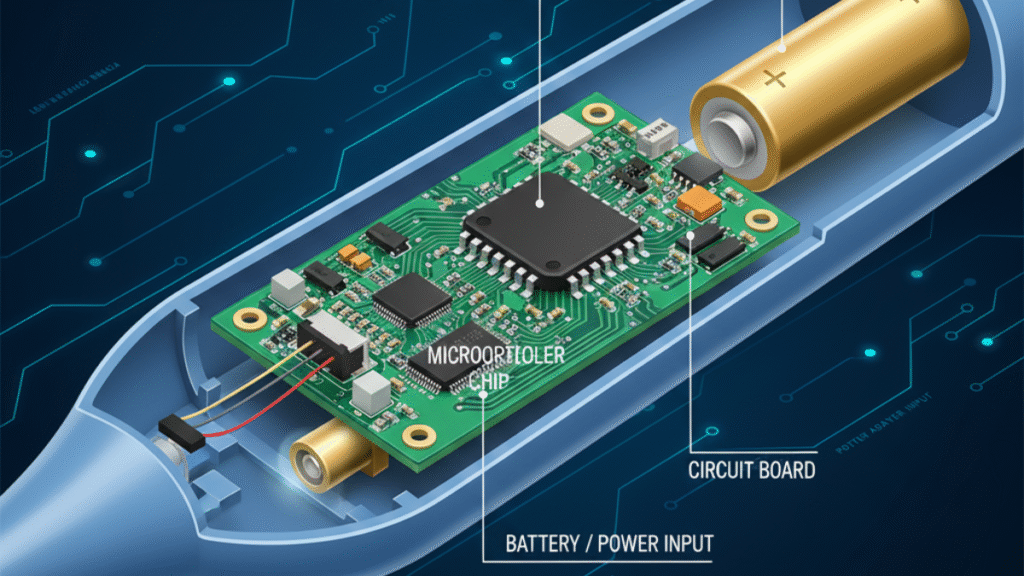

The digital thermometer represents a major technological leap, relying on electronic sensors and signal processing rather than visual observation. Three primary sensor technologies dominate digital thermometry: thermistors, thermocouples, and semiconductor sensors.

Thermistors

Thermistors are resistors whose resistance changes with temperature. In a typical digital thermometer, a Negative Temperature Coefficient (NTC) thermistor is used, meaning its resistance decreases as the temperature rises.

The thermometer’s electronic circuit measures this resistance change and converts it into a digital signal, which is then processed by a microcontroller to display the corresponding temperature.

Thermistors offer:

- High sensitivity in narrow temperature ranges.

- Rapid response times.

- Low cost.

However, they are non-linear, requiring complex calibration for accurate measurements.

Thermocouples

Thermocouples operate on the Seebeck effect, where two different metals joined at one end produce a voltage proportional to the temperature difference. Thermocouples are widely used in industrial thermometry because they can measure extremely high temperatures.

They require amplification and compensation circuits, which depend heavily on stable electrical power.

Semiconductor Sensors

Semiconductor-based sensors use temperature-dependent voltage characteristics of diodes or transistors. These are common in consumer-grade digital thermometers, offering compactness, durability, and integration with microcontrollers.

The Role of Power in Digital Thermometers

Unlike mercury or alcohol devices, digital thermometers require a continuous and stable power source. This is typically provided by:

- Batteries (for portable models).

- Power adapters (for professional and continuous-use devices).

Why is power stability so important?

- Sensor accuracy depends on stable bias voltages.

- Signal processing circuits (ADCs, amplifiers, microcontrollers) require a consistent supply.

- Voltage fluctuations can lead to erroneous readings, causing clinical misjudgments.

Clinical Case Example

Imagine a hospital ward where patients’ body temperatures are monitored continuously. If the thermometer’s power adapter suffers from voltage fluctuations, readings may drift by even 0.2 °C. In critical care, where precise monitoring of fever progression matters, such small errors can lead to misinterpretation of a patient’s condition.

Thus, the choice of power supply is not just a technical afterthought—it is directly tied to patient safety and diagnostic accuracy.

Infrared Thermometers and Non-Contact Technology

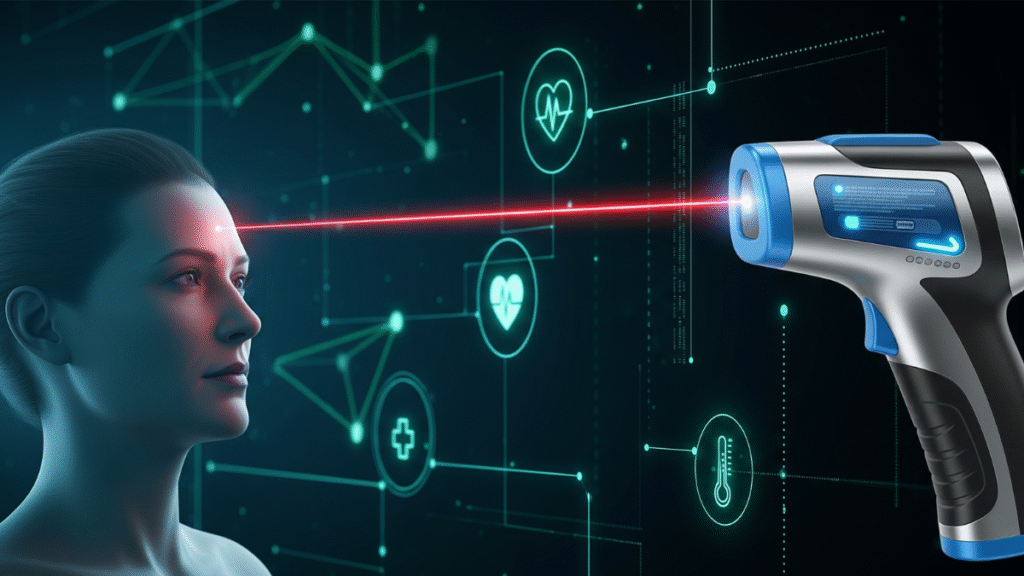

The COVID-19 pandemic popularized infrared (IR) thermometers, which measure temperature without physical contact. They work by detecting infrared radiation emitted from an object or person.

Infrared Radiation Principle

All objects above absolute zero emit infrared radiation. The intensity of this radiation increases with temperature. Infrared thermometers use sensors such as thermopiles or pyroelectric detectors to measure this radiation, which is then converted into a temperature reading.

Benefits of Non-Contact Measurement

- Hygienic, since there is no physical contact.

- Fast, producing results in under a second.

- Useful for screening large groups of people.

The Role of Power Supply

Infrared thermometers are more complex than digital contact thermometers. They require:

- High-gain amplifiers to detect small radiation signals.

- Analog-to-digital converters for precise digital output.

- Microprocessors to perform complex calculations and apply emissivity corrections.

These electronic circuits are extremely sensitive to power fluctuations. A noisy or unstable adapter can introduce significant errors by adding electrical noise to weak infrared signals.

Medical Power Standards

Medical infrared thermometers must comply with IEC 60601, the international standard for medical electrical equipment. This standard requires power supplies to minimize leakage current, resist electromagnetic interference, and ensure patient safety.

A compliant medical-grade power adapter ensures that the infrared thermometer not only works accurately but also meets regulatory requirements for clinical use.

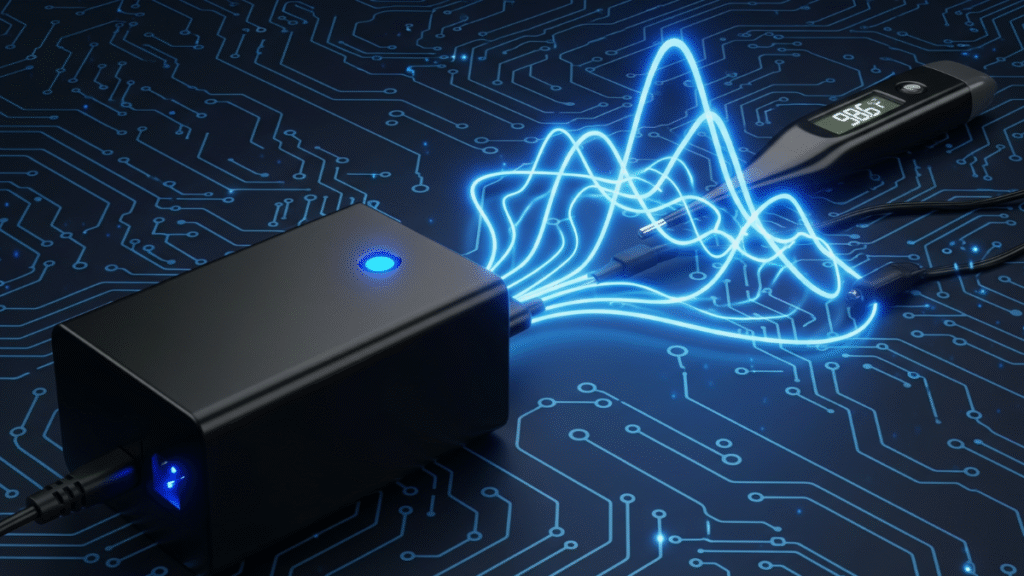

The Role of Power Adapters in Thermometers

Power adapters provide a bridge between the AC mains and the low-voltage DC required by thermometers. Their importance can be broken down into several key aspects:

- Voltage Stability

Stable voltage ensures sensors and microcontrollers operate within tolerance, preventing errors. - Noise Reduction

High-quality adapters reduce ripple and electromagnetic interference, critical for sensitive measurement circuits. - Portability vs Stationary Use

- Battery Power: Ideal for portable thermometers but limited by lifespan.

- Power Adapters: Preferred for continuous-use or stationary medical equipment where reliability is essential.

- Durability and Compliance

Medical-grade adapters must comply with IEC 60601, guaranteeing patient safety and minimizing interference with other hospital equipment.

Example: Portable vs Desktop Thermometers

- A handheld digital thermometer powered by batteries prioritizes convenience but may struggle with long-term calibration if battery voltage drops.

- A desktop clinical thermometer powered by an adapter offers consistent performance, longer service life, and integration with hospital data networks.

Temperature Measurement Errors and Power Factors

Temperature errors are not always due to the sensor itself; they can stem from the power supply.

Voltage Fluctuations

When the supply voltage fluctuates, the reference voltage of analog circuits shifts, leading to unstable readings. A mere 50 mV ripple can alter the displayed temperature by several tenths of a degree.

Electromagnetic Interference (EMI)

Thermometers in hospital environments often operate near other electronic equipment. Poorly shielded adapters can pick up or emit interference, disrupting sensitive circuits.

How to Minimize Errors

- Use medical-grade power adapters with low ripple and EMI suppression.

- Implement redundant filtering within the thermometer circuit.

- Ensure proper grounding to reduce leakage current.

By addressing power-related issues, manufacturers can significantly improve thermometer accuracy.

Future Trends

The future of thermometry is moving toward smart, connected devices.

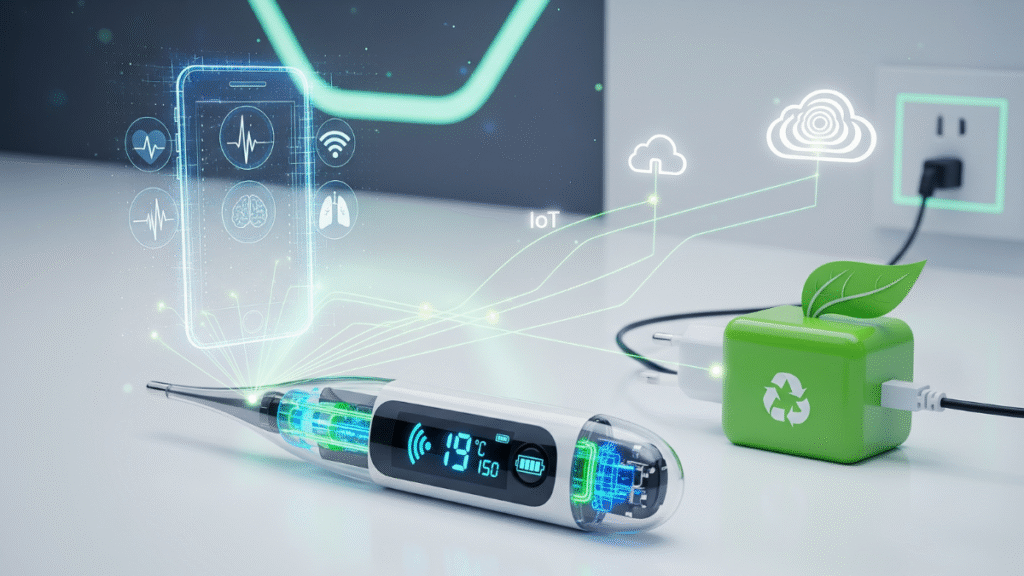

Smart Thermometers and IoT

Smart thermometers will transmit data wirelessly to healthcare platforms, enabling remote monitoring and telemedicine. This requires stable, efficient power sources to ensure uninterrupted connectivity.

Fast-Charging and Wireless Power

As thermometers become more advanced, demand grows for fast-charging batteries and wireless charging systems. Power adapters will evolve to deliver higher efficiency and flexibility.

Green Energy Considerations

Sustainability is becoming essential in medical equipment. Future power adapters for thermometers may integrate eco-friendly designs with lower standby consumption and recyclable materials.

Conclusion

The journey from mercury thermometers to modern infrared devices demonstrates the evolution of temperature measurement technology. While early thermometers functioned without electricity, today’s devices depend on precise, stable, and reliable power.

Power adapters are the unsung heroes of modern thermometry. They ensure stable operation, reduce noise, comply with safety standards, and ultimately safeguard accuracy in both medical and industrial applications. As thermometers continue to evolve toward smart and connected solutions, the demand for advanced power adapters will only grow.

Understanding how a thermometer works, therefore, is incomplete without recognizing the indispensable role of the power adapter. Together, they form a partnership that ensures every degree measured is a degree you can trust.