Medical devices like electrotherapy units carry direct contact with patients, which makes electrical safety a non-negotiable priority.

Medical power supplies ensure safety in electrotherapy units by limiting leakage current, meeting IEC 60601 standards, offering reinforced insulation, and including fail-safe protection mechanisms. These features reduce the risks of shock, fire, and interference.

When we develop or upgrade electrotherapy equipment, the power supply is often the first and last component we double-check. It’s not just about function — it’s about preventing harm. A well-designed medical power supply is the invisible protector that lets the therapy do its job, without risk to the patient or operator.

What Makes a Medical Power Supply Different from a Standard Power Adapter?

Safety problems can arise silently, and sometimes the damage is already done before you see any sign.

Medical power supplies differ from standard ones by strictly limiting leakage current, ensuring patient safety, meeting IEC 60601 certification, and offering double insulation and EMC shielding.

More Than Just Voltage and Amps

Choosing a medical-grade power supply is not about just matching voltage and current specs. Here’s what sets them apart:

| Feature | Medical Power Supply | Standard Power Supply |

|---|---|---|

| Safety Certification | IEC 60601, UL60601, EN60601 | UL/CE/FCC (non-medical) |

| Leakage Current | ≤ 100 μA (patient-connected), ≤ 500 μA (equipment) | Up to 3.5 mA |

| Isolation Protection | 2 x MOPP (Means of Patient Protection) | Basic or 1 x MOP |

| EMC Compliance | Medical EMC levels (EN 60601-1-2) | Industrial or consumer level |

| Component Aging | Stress-tested for hospital environment | Normal use conditions |

In one of our recent device upgrades, we once swapped out a generic adapter for a certified Class II medical supply, and the difference in electromagnetic noise, touch safety, and certification speed was immediately noticeable. There’s no substitute for purpose-built safety.

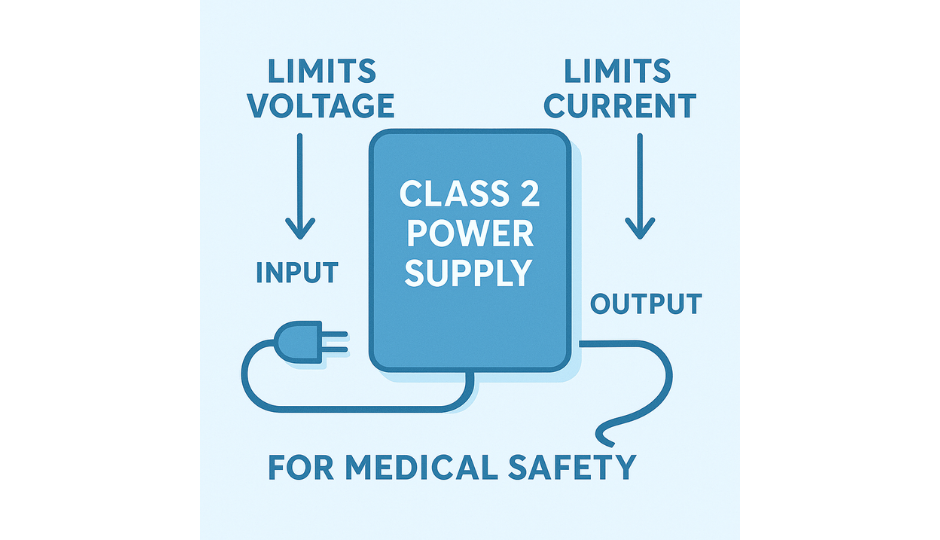

How Do Class Two Power Supplies Help Limit Risk?

Electrotherapy currents are low, but risks can still be high when the supply fails.

Class 2 power supplies help by limiting output to 60VDC and 100W, lowering the risk of fire and shock even in fault conditions. They are designed as Limited Power Sources (LPS).

Safety by Design, Not Just Labels

Class 2 (or Class II) power supplies do more than meet specs — they follow a design philosophy that makes failure unlikely and non-catastrophic when it happens. Here’s how:

- Power Limitation: Output is inherently capped to avoid delivering too much current in a fault.

- Thermal Control: Heat is managed through derating, shielding, and smart PCB layouts.

- Fault Tolerance: Even under short-circuit or overload, safety circuits shut down the output safely.

- Physical Separation: Components are arranged to prevent arc-over or current leakage.

For example, one of our customers developed a TENS therapy device for home use. By using a Class 2 certified power adapter, the product passed global safety standards in one go — no redesign, no certification delays, and zero reported field issues.

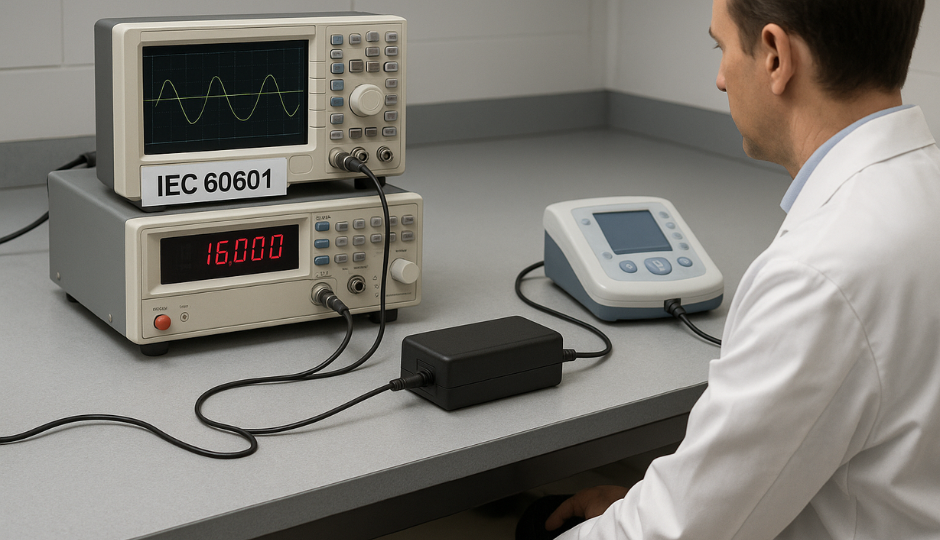

Why IEC 60601 Compliance Matters for Electrotherapy Power Design?

Powering a medical device is not the same as powering a lamp. Regulators see them differently, and so should we.

IEC 60601 ensures the power supply limits leakage, interference, and temperature rise — all essential when devices make direct contact with the human body.

Not Just Paperwork: What It Covers

Designing around IEC 60601 is demanding, but necessary. Here’s what it checks for power supplies:

- Dielectric Withstand: Must pass 4,000V AC surge test between primary and secondary circuits

- Creepage and Clearance: Ensures proper physical separation of conductors

- EMI and EMC Control: Keeps emitted noise low, avoids interference with other devices

- Temperature Rise: No component can exceed specific temperatures under max load

- Leakage Current: Must stay below dangerous thresholds in single-fault conditions

This is especially critical in electrotherapy, where electrodes might be attached to sensitive body areas. Any power instability or signal interference can cause discomfort or inaccurate treatment.

How Can Engineers Balance Safety, Cost, and Speed?

It’s easy to overdesign or overspend. The challenge is doing it fast, safely, and cost-effectively.

By selecting pre-certified, compact, and high-efficiency medical power supplies, engineers can avoid costly retesting and delays while meeting global safety standards.

What I’ve Learned from the Field

In my experience, when teams try to “custom-build” their power section or modify a generic one, they often spend months chasing down compliance issues, EMI noise, or borderline test results. On the other hand, using a pre-certified Class II medical-grade adapter:

- Cuts 6–8 weeks from the design cycle

- Avoids third-party safety redesigns

- Reduces compliance documentation burden

- Lowers the risk of recalls or certification failures

Most importantly, it frees your team to focus on what matters — the therapy, not the power brick.

Conclusion

Medical power supplies protect patients, ensure stable performance, and simplify global compliance for electrotherapy units.