Introduction

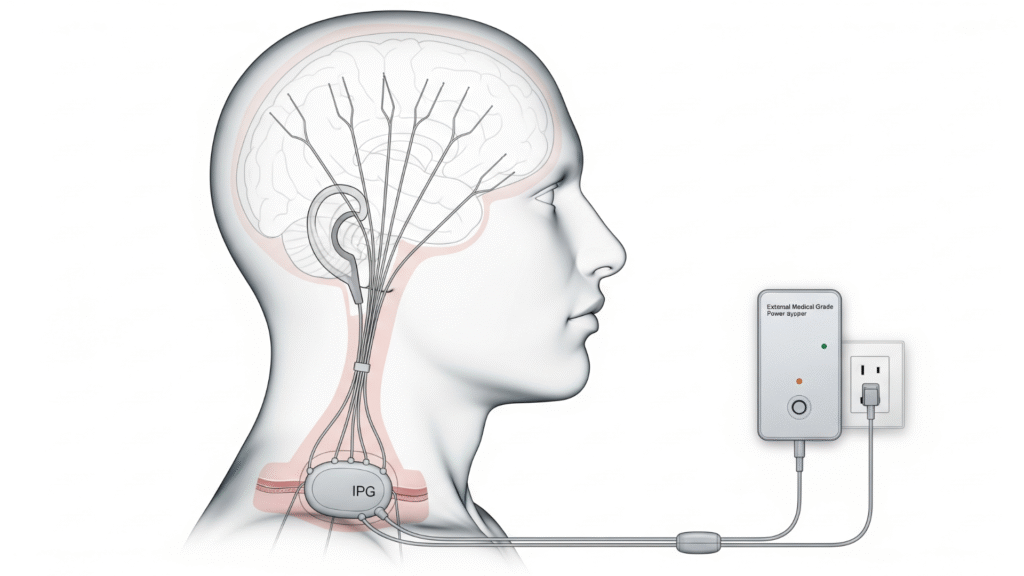

With the rapid advancement of medical technology, Deep Brain Stimulation (DBS) systems have become widely adopted for treating neurological disorders such as Parkinson’s disease, epilepsy, and depression. DBS systems deliver electrical pulses to specific brain regions through implanted electrodes to regulate abnormal neural activity and alleviate symptoms. However, the high precision and reliability requirements of DBS systems make them particularly sensitive to Electromagnetic Compatibility (EMC). As a critical component, the external switching power supply not only provides stable power but must also ensure minimal interference generation and immunity to external electromagnetic environments to safeguard patient safety and device performance.

Electromagnetic Compatibility refers to a device or system’s ability to operate normally in its electromagnetic environment without causing or suffering unacceptable electromagnetic interference (EMI). In medical devices, EMC is paramount, as EMI can lead to device malfunctions or even endanger patient lives. Due to their high-frequency switching characteristics, external switching power supplies are prone to generating EMI and must exhibit robust immunity to external interference. This article explores the key EMC compliance design considerations for external switching power supplies in DBS systems, integrating medical safety standards and analyzing critical technical strategies and implementation methods.

1. Overview of DBS Systems and External Switching Power Supplies

1.1 Composition and Functionality of DBS Systems

DBS systems typically consist of the following core components:

- Implantable Pulse Generator (IPG): Generates electrical pulses delivered to the brain via electrodes.

- Electrodes and Leads: Implanted in specific brain regions to transmit electrical signals.

- External Controller: Adjusts pulse parameters to control the treatment process.

- External Switching Power Supply: Provides stable power to the external controller or charging devices, typically delivering direct current (DC) output.

The primary function of DBS systems is to deliver precise electrical pulses to targeted brain areas, modulating neural activity to improve motor or psychiatric symptoms. Operating in complex environments, such as hospitals with strong electromagnetic fields (e.g., MRI machines, mobile communication devices), DBS systems demand stringent EMC performance from their external power supplies.

1.2 Role of External Switching Power Supplies in DBS Systems

External switching power supplies convert input alternating current (AC) to stable DC through high-frequency switching circuits, powering the external controller or charging components of DBS systems. Their advantages include high efficiency, compact size, and lightweight design. However, high-frequency switching operations generate significant EMI, including conducted and radiated interference, which can propagate through power lines or space, potentially disrupting DBS system functionality or other medical equipment. Thus, the design of external switching power supplies must balance efficient power conversion with strict EMC compliance.

2. Key EMC and Medical Safety Requirements

2.1 EMC Standards for Medical Devices

EMC design for medical devices must comply with international and industry standards, with the most critical being:

- IEC 60601-1-2: The electromagnetic compatibility standard for medical electrical equipment, covering electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) testing requirements.

- EMI Testing: Includes radiated emissions, conducted emissions, harmonic currents, and voltage flicker.

- EMS Testing: Includes electrostatic discharge (ESD), electrical fast transient/burst (EFT/B), surge, and voltage dips/interruptions.

- ISO 14708-3: Specific EMC requirements for implantable neurostimulators, emphasizing immunity for DBS systems.

- CISPR 11: Limits and measurement methods for radio-frequency interference from industrial, scientific, and medical equipment.

These standards mandate that medical devices operate normally in electromagnetic environments without producing unacceptable interference. Given their direct interaction with the human body, DBS systems must meet stringent Class A or B EMC requirements to ensure safety.

2.2 Relationship Between Medical Safety and EMC

Electromagnetic interference can cause the following issues in DBS systems:

- Signal Distortion: Interference may alter the pulse generator’s output, reducing treatment efficacy.

- Device Malfunction: External electromagnetic fields could trigger unintended behavior in controllers or power supplies.

- Patient Safety Risks: Severe interference may lead to device failure, posing life-threatening risks to patients.

Thus, EMC design for external switching power supplies is not only a technical requirement but also a cornerstone of medical safety. Key considerations include:

- Minimizing generated EMI.

- Enhancing immunity to external electromagnetic interference (EMS).

- Complying with medical device regulations (e.g., EU MDR, US FDA requirements).

3. EMC Compliance Design Considerations for External Switching Power Supplies

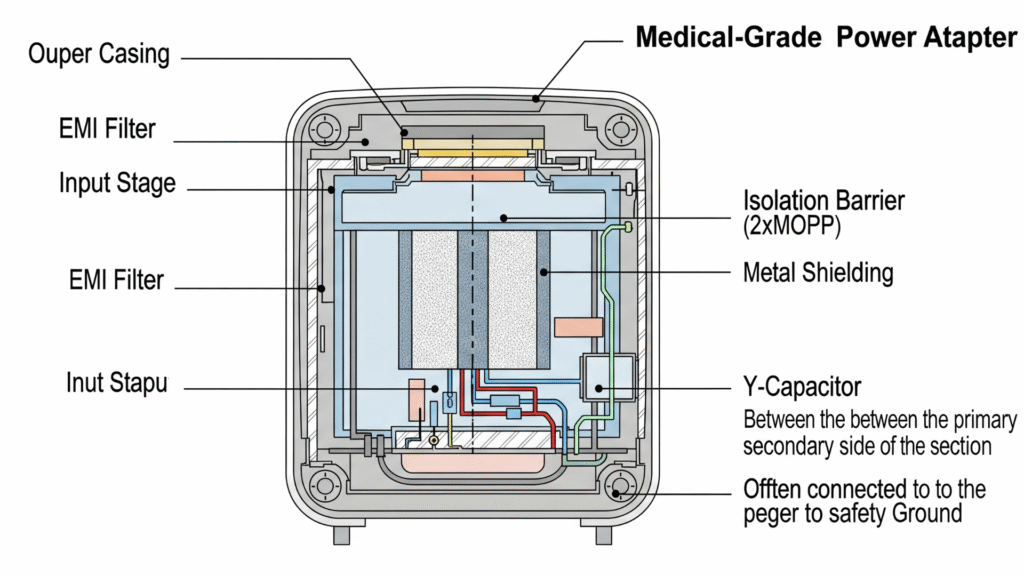

3.1 Input Filter Circuit Design

High-frequency switching in power supplies generates conducted and radiated interference, making input filter circuits critical for suppressing conducted EMI. Design considerations include:

- Common-Mode and Differential-Mode Filtering:

- Common-mode interference: Suppressed using common-mode chokes and Y-capacitors.

- Differential-mode interference: Mitigated with X-capacitors and differential-mode inductors.

- Optimized Filter Topology: Employ multi-stage filter circuits (e.g., π-type or T-type filters) to enhance suppression while avoiding overly complex designs that increase costs.

- Grounding Design: Ensure short, low-impedance grounding paths to prevent ground loop interference.

3.2 PCB Layout Optimization

The printed circuit board (PCB) layout significantly impacts EMC performance, particularly in high-frequency switching power supplies. Key design principles include:

- Signal Isolation: Separate high-frequency switching circuits from low-voltage control circuits to reduce coupling interference.

- Short Path Design: Minimize high-frequency current loop paths to reduce radiated interference.

- Ground Plane: Use a complete ground plane to provide a low-impedance return path, reducing common-mode interference.

- Decoupling Capacitors: Place high-frequency decoupling capacitors near critical components (e.g., MOSFETs, controller ICs) to suppress voltage spikes.

3.3 Switching Frequency and Control Strategies

Switching frequency selection directly affects EMC performance:

- Frequency Optimization: Choose an appropriate switching frequency (e.g., 100 kHz to 500 kHz) to avoid overlap with DBS system signal frequencies or external medical equipment (e.g., MRI).

- Soft Switching Techniques: Implement Zero Voltage Switching (ZVS) or Zero Current Switching (ZCS) to reduce high-frequency noise during switching.

- Frequency Modulation: Use Spread Spectrum Frequency Modulation to distribute interference energy across a wider frequency band, lowering peak interference.

3.4 Shielding and Enclosure Design

Radiated interference from switching power supplies can be effectively controlled through shielding:

- Metal Enclosure: Use highly conductive metal enclosures (e.g., aluminum alloy) with proper grounding.

- Shielding Materials: Add shielding cans to critical PCB areas to suppress high-frequency radiation.

- Seam Control: Ensure tight enclosure seams to prevent electromagnetic wave leakage.

3.5 Immunity Design

DBS systems may be exposed to strong electromagnetic fields in hospital environments (e.g., MRI, mobile signals), requiring high immunity in external power supplies:

- Electrostatic Discharge (ESD) Protection: Add TVS diodes or ESD protection devices at power input ports and critical signal lines.

- Surge Protection: Use varistors or gas discharge tubes to protect against lightning or surge impacts.

- Fast Transient Immunity: Enhance immunity to electrical fast transients through optimized filtering and transient suppression devices.

4. Special Design Considerations for DBS-Specific Power Supplies

4.1 Low-Noise Design

DBS systems are highly sensitive to power supply noise, as ripple or noise can interfere with the pulse generator’s precise output. Design considerations include:

- Low Ripple Output: Use LC filters or linear regulators to smooth the output voltage.

- High PSRR Design: Select regulators with high Power Supply Rejection Ratio (PSRR) to suppress input noise effects on the output.

- Isolation Design: Employ high-isolation transformers (e.g., medical-grade isolation transformers) to reduce noise coupling between input and output.

4.2 Medical-Grade Safety Isolation

Per IEC 60601-1 standards, medical devices require stringent electrical isolation to prevent leakage currents from harming patients. Design considerations for power supplies include:

- Reinforced Insulation: Ensure isolation voltage exceeds 4 kV between input and output.

- Low Leakage Current: Control leakage current below 10 μA to meet requirements for patient-contact devices.

- Dual Protection: Add optocouplers or relays beyond isolation transformers to enhance safety.

4.3 Environmental Adaptability

External power supplies for DBS systems may be used in various environments (e.g., hospitals, homes), requiring:

- Wide Input Voltage Range: Supports 85V–265V input to accommodate global grid standards.

- Temperature and Humidity: Ensure stable operation in 0°C to 50°C and up to 90% humidity.

- Compact Design: Minimize size while meeting EMC and safety requirements for patient portability.

5. EMC Testing and Validation

5.1 Pre-Compliance Testing

Pre-compliance testing is essential to validate EMC design effectiveness before formal certification. Common tests include:

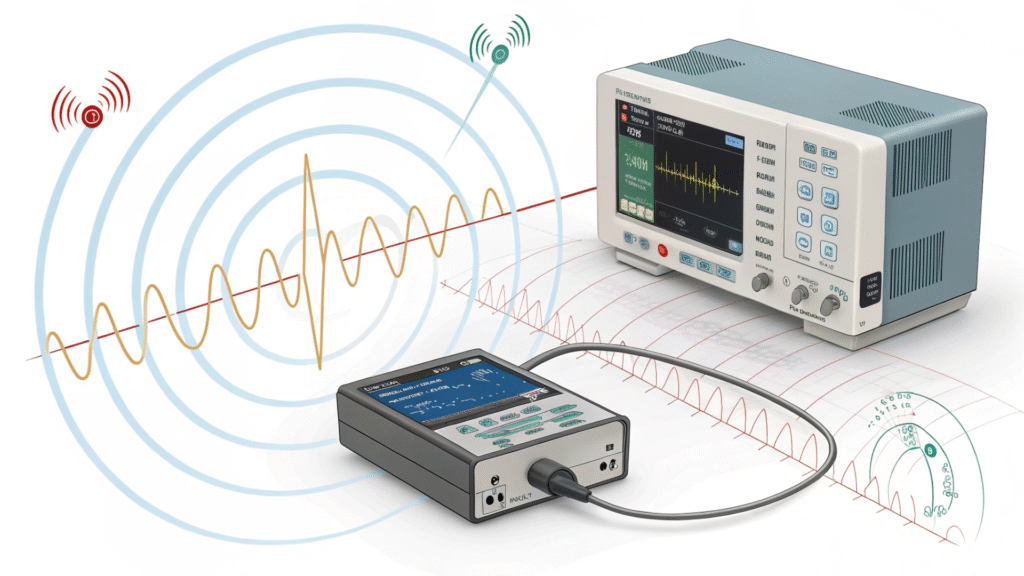

- Conducted Emission Testing: Measure conducted interference at the power input using a Line Impedance Stabilization Network (LISN).

- Radiated Emission Testing: Assess radiated emissions in an anechoic chamber.

- Immunity Testing: Simulate external interference such as ESD, surges, and fast transients to verify robustness.

5.2 Field Testing

Given the hospital environments where DBS systems are used, field EMC testing is critical. Tests include:

- MRI Compatibility: Verify power supply immunity in strong magnetic field environments.

- Multi-Device Interference: Simulate scenarios with multiple electronic devices operating simultaneously to test EMC performance.

5.3 Certification Process

EMC certification is mandatory for DBS system market entry. The process includes:

- Submitting design documentation and test reports.

- Conducting formal testing in accredited laboratories (e.g., Tektronix, Keysight).

- Obtaining CE, FDA, or other regional certification marks.

6. Case Study and Practical Insights

6.1 Case Study: EMC Rectification for a DBS Power Supply

In an initial test, an external switching power supply for a DBS system exhibited excessive conducted emissions. Rectification measures included:

- Adding Common-Mode Chokes: Implemented two-stage common-mode chokes at the input to reduce high-frequency noise.

- Optimizing PCB Layout: Separated high-frequency switching and control circuits to minimize coupling.

- Adjusting Switching Frequency: Shifted the frequency from 200 kHz to 150 kHz to avoid conflicts with DBS system signals.

Post-rectification, the power supply passed IEC 60601-1-2 testing, with conducted emissions reduced below standard limits.

6.2 Practical Insights

- Early Design Integration: Incorporate EMC considerations from the initial design phase to avoid costly rectifications.

- Multidisciplinary Collaboration: EMC design requires coordination among circuit design, mechanical design, and software control teams to ensure system-wide performance.

- Continuous Optimization: Conduct multiple pre-compliance tests to iteratively refine designs and reduce certification risks.

7. Future Trends

7.1 New Materials and Technologies

Advancements in materials (e.g., high-permeability ferrites) and technologies (e.g., GaN switching devices) will enhance EMC performance. GaN devices, with their high switching speeds and low losses, can significantly reduce EMI while improving power efficiency.

7.2 Intelligent Design

Intelligent control technologies, such as adaptive frequency regulation, can dynamically adjust switching frequencies based on environmental electromagnetic conditions, further optimizing EMC performance.

7.3 Stricter Standards

With the rise of 5G and IoT technologies, medical devices face increasingly complex electromagnetic environments, likely leading to stricter EMC standards. This will drive power supply designs toward higher immunity and lower interference.

8. Conclusion

EMC-compliant design of external switching power supplies is critical for ensuring the safety and reliability of DBS systems. By optimizing input filtering, PCB layout, switching frequency, shielding, and immunity measures, designers can effectively reduce EMI and enhance resistance to external interference. Compliance with medical EMC standards like IEC 60601-1-2, coupled with rigorous testing and validation, is essential for success. Looking forward, advancements in materials and intelligent technologies will further improve the EMC performance of power supplies, providing robust support for the safe application of DBS systems.