Introduction

Class 2 power supply cords represent a critical component in modern low-voltage power delivery systems. Unlike high-voltage cords, which require extensive insulation, grounding, and specialized handling, Class 2 cords operate within strictly limited voltage and current parameters, providing an inherently safe solution for a wide range of devices.

From consumer electronics such as routers, cameras, and smart home devices, to industrial automation sensors, Point-of-Sale (POS) systems, and medical equipment, Class 2 cords are ubiquitous yet often overlooked.

The primary advantage of a Class 2 power supply cord is its energy-limiting design, which prevents electric shock and fire hazards, even if the cord is damaged or improperly handled. These cords are defined by national and international standards, including UL 1310, IEC 62368-1, and NEC Article 725, which dictate voltage, current, insulation, and installation requirements. Compliance ensures both manufacturer accountability and user safety, while simplifying regulatory approval in global markets.

This article provides a comprehensive technical overview of Class 2 power supply cords. Topics include their specifications, safety mechanisms, applications across industries, technical design considerations, comparisons with other classes, emerging trends, and best practices for design, procurement, and integration. The goal is to equip engineers, designers, and procurement professionals with a deep understanding of Class 2 cords, enabling safer, more efficient, and future-ready low-voltage power solutions.

Chapter 1: Understanding Class 2 Power Supply Cords

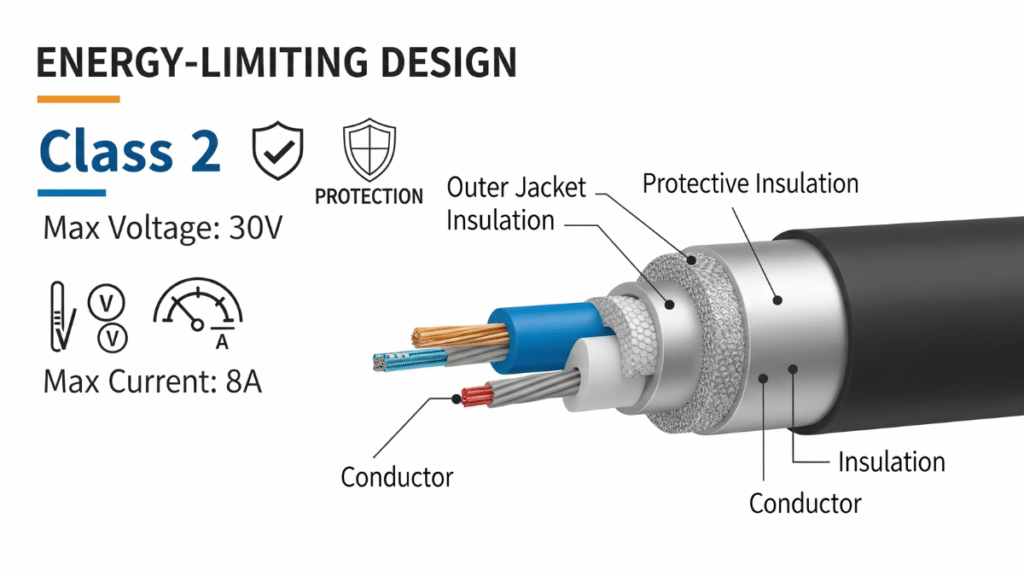

Class 2 power supply cords are low-voltage cords designed to limit the energy delivered to connected devices. According to UL and NEC definitions, a Class 2 circuit typically operates below 30V RMS (42.4V peak) AC or 60V DC and provides current-limited power to prevent hazardous situations.

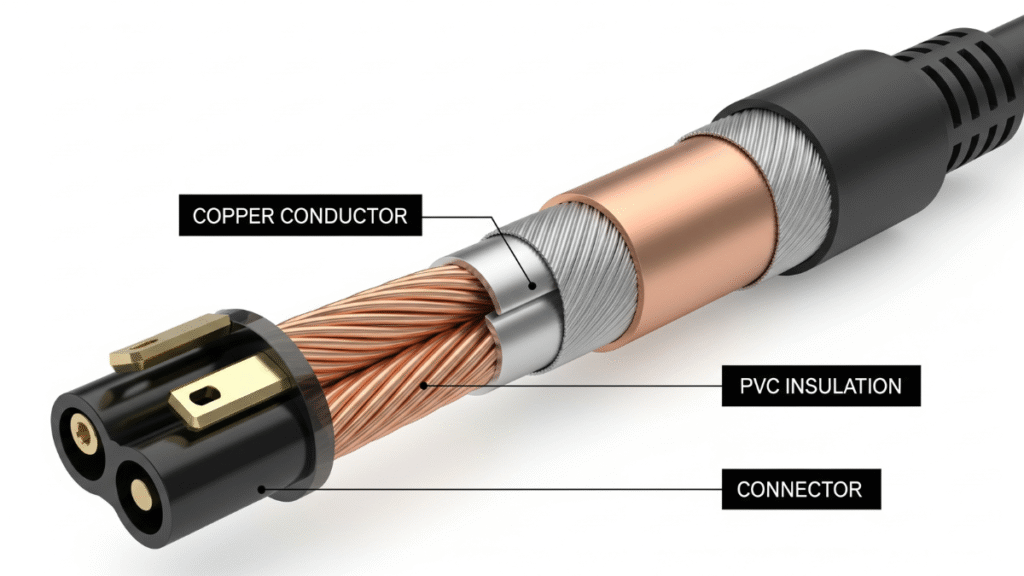

1.1 Design Characteristics

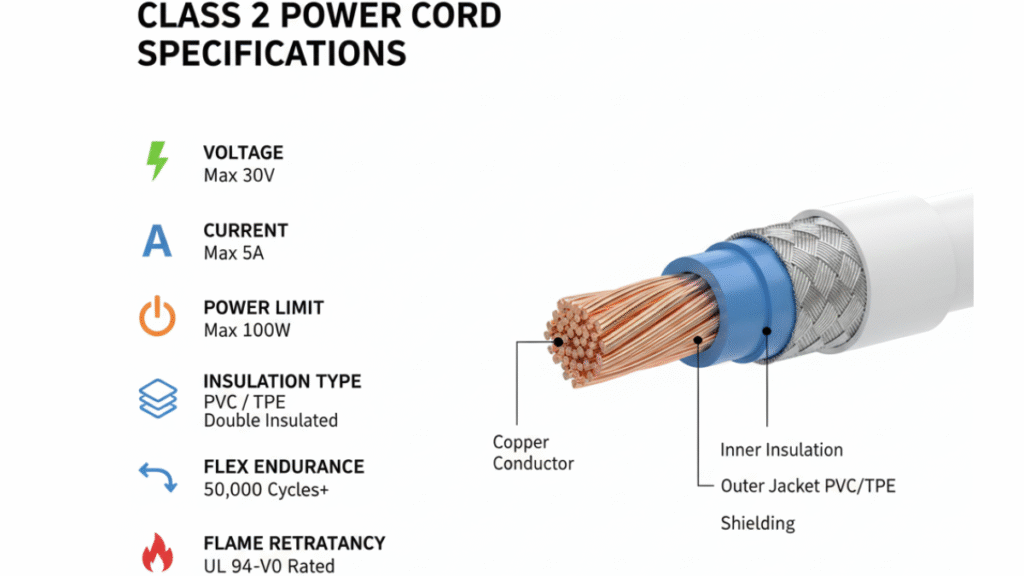

- Conductor: Copper with appropriate gauge for current limits.

- Insulation: PVC, TPE, or silicone rated for temperature, chemical resistance, and mechanical flexibility.

- Connectors: Barrel jacks (2.1mm, 2.5mm), USB-C, or proprietary locking connectors.

1.2 Safety Principle

The inherent energy limitation eliminates the need for protective grounding, making these cords safe to handle by end-users. The cords are also constructed to withstand mechanical stress, bending, and minor environmental exposure.

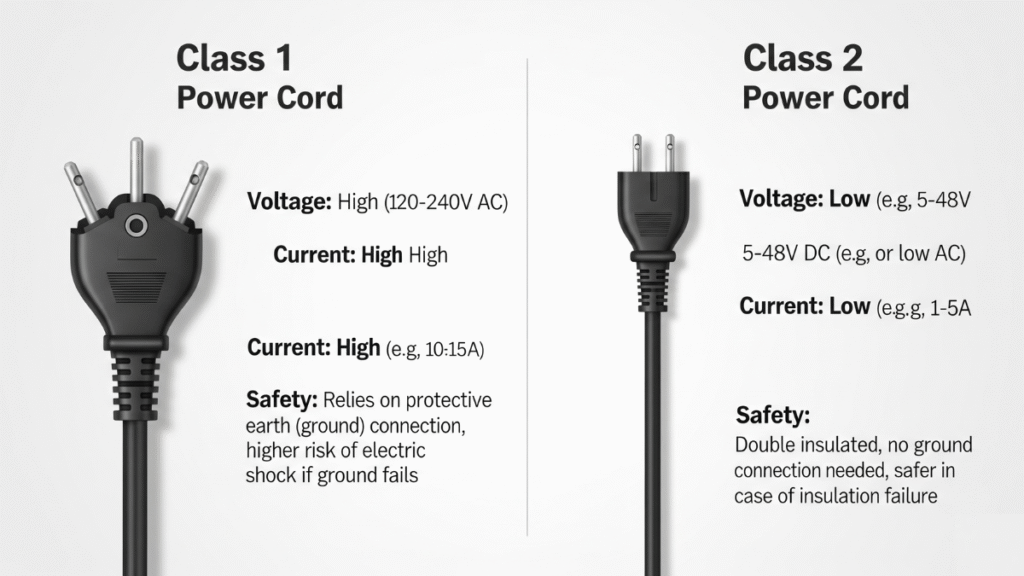

1.3 Comparison with Other Classes

- Class 1: High-voltage, high-current; requires grounding and specialized installation.

- Class 2: Low-voltage, limited energy, safe for end-users, widely used.

- Class 3: Higher low-voltage, additional protective measures needed; niche applications.

Class 2’s combination of safety, simplicity, and regulatory compliance makes it the most widely adopted class for low-voltage power delivery.

Technical Parameters Example

Voltage: ≤ 30V RMS AC / 60V DC

Current: Limited according to UL 1310

Power: Typically below 100W

✅ Tip: Always verify the voltage and current ratings with the corresponding power adapter certification to ensure Class 2 compliance.

Chapter 2: Technical Specifications

2.1 Electrical Parameters

- Voltage: ≤ 30V RMS AC or 60V DC

- Current: Limited according to UL 1310 specifications; varies with wire gauge and cord length

- Power: Typically below 100W; sufficient for consumer electronics, sensors, and low-power industrial devices

2.2 Insulation and Jacket Materials

- PVC: Economical, suitable for indoor consumer devices

- TPE / CPE: Flexible, chemical and heat resistant; suitable for industrial applications

- Silicone: High temperature tolerance, ideal for medical devices requiring sterilization

2.3 Environmental and Mechanical Properties

- Temperature range: -20°C to +105°C depending on material

- Flexibility and bend endurance: Must survive repeated manipulation

- Chemical and UV resistance: Required for outdoor or industrial installations

- Flame retardancy: UL 94 V-0 or equivalent

2.4 Standards Compliance

- UL 1310: Defines Class 2 power units and their compatible cords

- IEC 62368-1 / 60601-1: Safety standards for audio/video, IT, and medical devices

- NEC Article 725: Installation standards for Class 2 wiring

- RoHS / REACH: Material safety and environmental compliance

⚠️ Warning: Using non-compliant cords in regulated equipment can lead to safety hazards and legal liabilities.

Chapter 3: Safety Mechanisms and Limitations

3.1 Energy Limitation

- Voltage and current caps prevent dangerous electric shock

- Short-circuit safety: Even in short-circuit conditions, the cord cannot deliver lethal energy

3.2 Insulation and Mechanical Protection

- Double or reinforced insulation reduces risk of leakage

- Flexible jackets and strain relief prevent mechanical failure at connectors

3.3 Environmental Constraints

- Indoor cords: moderate temperature and humidity limits

- Outdoor/industrial cords: chemical, UV, and moisture resistance required

3.4 Regulatory Compliance

- UL, IEC, and NEC adherence ensures cords meet safety standards for their intended application

- Medical devices: IEC 60601-1 testing ensures patient safety against leakage currents

✅ Tip: Always check environmental ratings and certifications for your intended application.

Chapter 4: Applications of Class 2 Power Supply Cords

4.1 Consumer Electronics

- Devices: Routers, Wi-Fi extenders, smart speakers, LED lighting, cameras

- Requirements: Compact, low-voltage, safe for user handling

4.2 IT Equipment

- Devices: IP phones, network switches, POS terminals, external storage

- Requirements: Modular connectors, regulatory compliance, EMI shielding

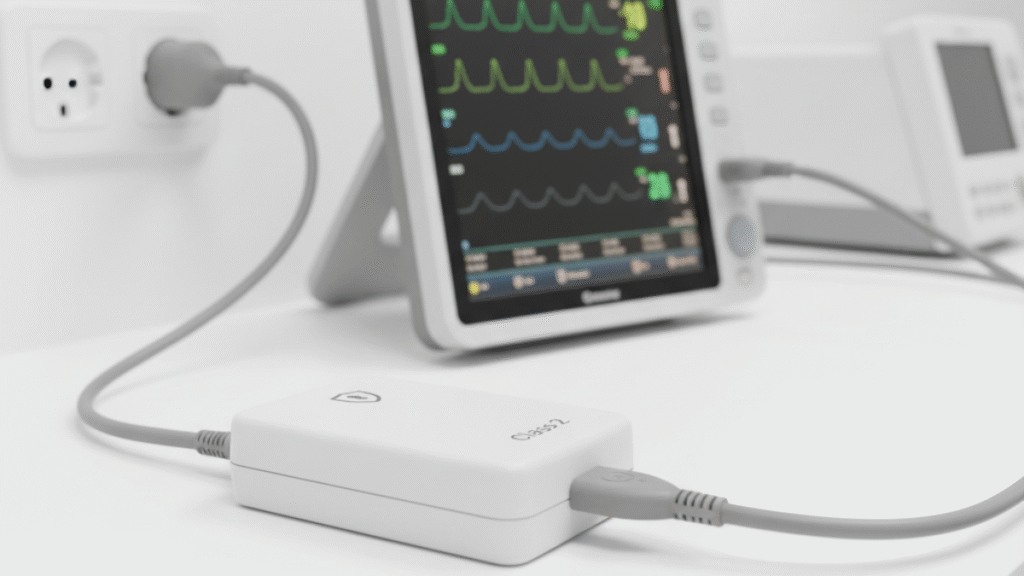

4.3 Medical Devices

- Devices: Patient monitors, portable analyzers, home healthcare devices

- Requirements: Low leakage, IEC 60601 compliance, sterilizable materials

4.4 Industrial Automation

- Devices: Sensors, actuators, HVAC controllers, vision systems

- Requirements: Robust insulation, chemical and heat resistance, strain relief

4.5 IoT and Renewable Systems

- Devices: Smart meters, battery management systems, gateways

- Requirements: Low-voltage safe delivery, environmental resistance, compatibility with future upgrades

💡 Note: Class 2 cords support safe, standardized, and cost-effective power distribution across all sectors.

Chapter 5: Safety and Compliance Considerations

5.1 Standards Overview

- UL 1310 / 62368-1: Defines construction, insulation, current/voltage limits

- IEC 60601-1: Medical device safety, patient leakage limits

- NEC Article 725: Installation practices for Class 2 wiring

5.2 Installation Guidelines

- Separation from Class 1 circuits to prevent accidental contact

- Correct polarity and connector matching

- Proper wire gauge for voltage drop management

- Environmental considerations: outdoor or industrial conditions

5.3 Testing and Certification

- Dielectric strength, insulation resistance, flame resistance, flex endurance, strain relief

- Certification labels: UL, CSA, CE, RoHS

- Medical cords: additional leakage current and biocompatibility tests

5.4 Importance of Compliance

- Protects users, ensures legal marketability, and maintains brand trust

Chapter 6: Technical Design Considerations

6.1 Electrical Design

- Conductor sizing to handle current

- Voltage drop analysis over cord length

- Shielding for EMI-sensitive devices

6.2 Environmental Factors

- Temperature, moisture, chemical, and UV resistance

- Bend endurance and fire safety

6.3 Integration with Power Supply

- Connector compatibility, strain relief, modular vs. hardwired design

- Full system certification with adapters

6.4 Cost, Safety, and Performance Trade-offs

- Balancing materials, insulation, and certification costs against durability and efficiency

Chapter 7: Comparison with Other Classes

| Class | Voltage / Current | Safety | Applications | Complexity |

|---|---|---|---|---|

| Class 1 | High | Requires grounding | Appliances, industrial | High |

| Class 2 | Low, limited | Inherently safe | Consumer, medical, industrial low-power | Low |

| Class 3 | Moderate | Requires some protection | Niche low-voltage | Medium |

💡 Note: Class 2 provides an optimal balance between safety, simplicity, and cost for most low-voltage applications.

Chapter 8: Emerging Trends

- USB-C and PD3.1 Integration: Class 2 cords increasingly support USB-C connectors for fast charging and data integration.

- IoT and Smart Devices: Low-voltage power distribution using Class 2 cords is growing with smart sensors and home automation.

- Advanced Materials: High-flexibility TPE and silicone cords improve durability and environmental resilience.

- Regulatory Expansion: Global adoption of IEC and UL standards ensures worldwide compliance and safety.

Chapter 9: Best Practices for Procurement and Usage

- Verify Certification: Ensure cords comply with UL, IEC, and local standards.

- Check Environmental Ratings: Use the correct jacket material for intended indoor/outdoor conditions.

- Ensure Proper Connector Compatibility: Match voltage, polarity, and connector type.

- Plan for Lifecycle and Maintenance: Consider replacement cycles for high-use or industrial applications.

- Educate End Users: Provide guidance for safe handling and installation.

Chapter 10: Conclusion

Class 2 power supply cords are essential components in modern low-voltage applications. Their energy-limiting design, safety compliance, and versatility make them suitable for consumer electronics, medical devices, industrial automation, and IoT systems. By understanding specifications, regulatory requirements, environmental considerations, and emerging trends, engineers, designers, and procurement professionals can ensure safety, reliability, and efficiency in every application.

✅ Final Tip: Always integrate Class 2 cords in accordance with the device specifications, environmental conditions, and regulatory requirements to maximize safety and performance.