The wrong power supply can cause silent failures, uncomfortable patient experiences, or even critical safety issues. That’s why I pay extra attention to the power sources behind electric hospital beds.

Electric hospital beds need Class 2 and open-frame power supplies because they provide limited power output for safety, are easier to integrate into compact bed structures, and reduce the risk of shock or overheating during use.

If you’ve ever worked with powered hospital equipment, you know that what lies under the surface often matters most. Choosing the wrong type of power adapter may never be visible to patients, but it shows up in maintenance costs, safety alerts, and poor motion control. I’ve seen that firsthand, and that’s why I believe this topic is more than just technical — it’s essential.

What Makes Class 2 Power Supplies Essential for Hospital Beds?

Even with compact designs and quiet motors, electric hospital beds operate in an environment where patient safety is non-negotiable. If the power fails, or worse — overheats — the risk goes far beyond inconvenience.

Class 2 power supplies are designed with current and voltage limitations that protect patients from electrical hazards and meet strict medical safety standards like UL 1310 and IEC 60601-1.

Why Low-Voltage, Current-Limited Power is Key

When we’re selecting components for electrically adjustable beds — height, leg, and backrest — we’re powering small DC motors. These motors don’t need high voltage, but they need consistency and protection. That’s where Class 2 power supplies stand out. Their current is inherently limited to prevent excess heat, short circuits, or even fires. In a hospital, even a moment of power surge can be disastrous.

Here’s a breakdown of how Class 2 power supply compares to non-Class 2 units:

| Feature | Class 2 Power Supply | Non-Class 2 Power Supply |

|---|---|---|

| Max Power Output | 100VA or less | Often exceeds 100VA |

| Safety Certification | UL 1310, IEC 60601-1 compliant | May lack medical compliance |

| Shock Risk | Low | Higher |

| Installation Approval Time | Fast | Slower due to testing needs |

| Maintenance Risk | Low (limited failures) | High |

We once tested a non-Class 2 unit inside an adjustable ICU bed during a pilot run. After six weeks, the internal wiring insulation was compromised due to heat. We replaced it with a certified Class 2 adapter — no more issues since.

Why Are Open-Frame Power Supplies Preferred by Designers?

Space inside an electric hospital bed frame is extremely limited. We have motion controllers, sensors, and linear actuators all tucked into one moving unit. So traditional, bulky power bricks simply don’t fit.

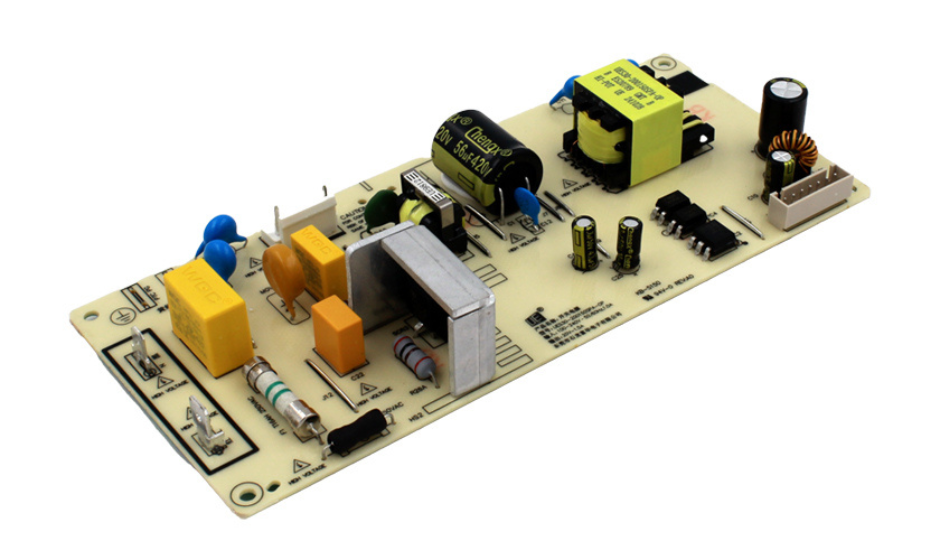

Open frame power supplies allow for flexible, compact installation directly onto the control board or inside the mechanical housing of the bed, making them ideal for space-constrained medical designs.

Integrating Power Without Compromising Space or Cooling

A sealed adapter traps heat. That’s fine for a desktop device. But in a hospital bed frame, airflow is restricted. We often place the power module close to moving parts or near foam padding. That’s a thermal hazard.

Open frame designs help us dissipate heat more efficiently. Plus, they come in customizable PCB sizes. During one of our mid-tier hospital bed development cycles, switching to an open-frame power supply gave us an extra 12mm of design clearance. That small gain allowed us to include a sensor for bed angle calibration — a feature the customer loved.

Here’s why open frame supplies are increasingly used in electric hospital beds:

| Advantage | Impact on Bed Design |

|---|---|

| Smaller footprint | Fits within narrow frame or control board space |

| Better heat management | No plastic enclosure = faster cooling |

| Lightweight | Reduces total bed weight |

| Easier customization | Allows OEM-specific voltage/pinout adjustments |

An open frame also makes post-install testing simpler. Engineers can probe voltage or current directly on the exposed board without disassembling the housing — something every repair technician appreciates.

How Do These Power Choices Improve Patient Experience?

Patients don’t think about power supplies. But they feel the results. A hospital bed that jerks, delays, or overheats during adjustment directly affects comfort and trust.

Using stable, certified Class 2 and open frame power supplies ensures smooth motor operation, minimal electrical noise, and consistent performance during patient movement or bed control.

Quiet, Reliable Movement Matters More Than You Think

I remember a post-op patient complaining that her bed lift jolted during the operation. The issue wasn’t with the motor — it was the adapter. It couldn’t deliver a consistent voltage under varying loads. Once we replaced it with a Quankang open frame Class 2 unit, the motion became seamless.

Power supply inconsistency often shows up as:

- Bed shaking or jerky motion during angle adjustments

- Delayed control panel response

- Overheating around the motor area

- Repeated service calls from the nursing staff

By using certified, well-engineered supplies, we reduce all of these. In critical care, that means smoother nurse workflows, fewer patient complaints, and better rest outcomes.

Even more, the safety benefits also build trust with hospital buyers. Compliance with IEC 60601-1 isn’t just a checkbox — it’s a requirement that reduces liability and reassures regulatory bodies.

Conclusion

Electric hospital beds need the right power — and that means Class 2 safety and open frame flexibility for reliable, quiet, and safe patient care.