LED strip lights have become one of the most versatile and efficient lighting options available today. From modern homes and architectural lighting to commercial displays and signage, their flexibility and energy efficiency make them ideal for countless applications. Yet, one component is often overlooked but essential — the power adapter. Without the right adapter, LED strips cannot operate safely or reliably. Choosing the proper adapter involves understanding voltage, current, wattage, and the specific requirements of the LED system. This article explores in detail how LED strip adapters work, how to select the right one, and how to ensure safe and stable performance in every application.

Every LED strip operates on low-voltage direct current (DC), typically 12 volts or 24 volts. However, the electricity supplied to our homes and businesses is high-voltage alternating current (AC), usually ranging from 100 to 240 volts depending on the region. The adapter’s primary job is to convert this high-voltage AC power into the low-voltage DC output that LED strips require. In addition to conversion, a well-designed adapter regulates the current to prevent fluctuations that could damage the LEDs. LEDs are current-sensitive components; even small changes in voltage can affect their brightness or shorten their lifespan. A stable adapter ensures the LEDs maintain consistent illumination and color temperature over time.

To understand how to choose the right adapter, it’s important to start with the basic electrical parameters. The first is voltage. The voltage of the adapter must always match the voltage of the LED strip. If the strip is rated for 12V, then the adapter must provide 12V DC. Using a higher voltage, such as 24V, will immediately damage the LEDs. The second key factor is current. Current determines how much electrical flow is required to power the LEDs. LED strips specify current indirectly through power consumption per meter. Power, measured in watts, equals voltage multiplied by current (P = V × I). If a 12V LED strip consumes 4 amps, its total power draw is 48 watts. For safety and efficiency, engineers recommend choosing an adapter with at least 20–30% higher wattage capacity than the calculated load. This margin ensures the adapter doesn’t operate at its maximum limit, preventing overheating and extending its lifespan.

Adapters for LED strip lights come in several types, each suited for different environments and power levels. The most common type is the wall plug adapter. It integrates directly with an AC wall socket and typically provides up to around 60 watts of output. These adapters are ideal for short LED strips used for under-cabinet lighting, home decoration, or small displays. They are compact, easy to use, and affordable. However, their small size limits power output and thermal performance, making them unsuitable for large installations.

For medium-sized lighting systems, desktop adapters are more practical. Similar in design to a laptop charger, they offer higher power ratings—often 60 to 150 watts—and feature a cable between the adapter body and the wall plug. This separation allows for better heat dissipation and flexible placement. Desktop adapters are popular in retail lighting, office environments, and custom installations where a neat, portable design is desired.

For heavy-duty or professional applications, open-frame power supplies are used. These units have metal enclosures, ventilation holes, and terminal blocks instead of fixed plugs. They can deliver hundreds of watts and are often mounted inside control panels or behind display walls. Because they are exposed designs, they require professional installation and must comply with electrical safety standards.

Matching voltage and current is the foundation of LED strip design, but wiring configuration also plays a major role. When connecting multiple LED strips to one adapter, parallel wiring is recommended. This ensures each strip receives the same voltage directly from the power source. In contrast, connecting strips in series causes voltage to drop along the circuit, leading to uneven brightness and color fading in distant sections. For long LED runs—especially over 10 meters—power injection points should be added at intervals to maintain brightness consistency. This technique redistributes the current evenly and reduces the strain on the adapter.

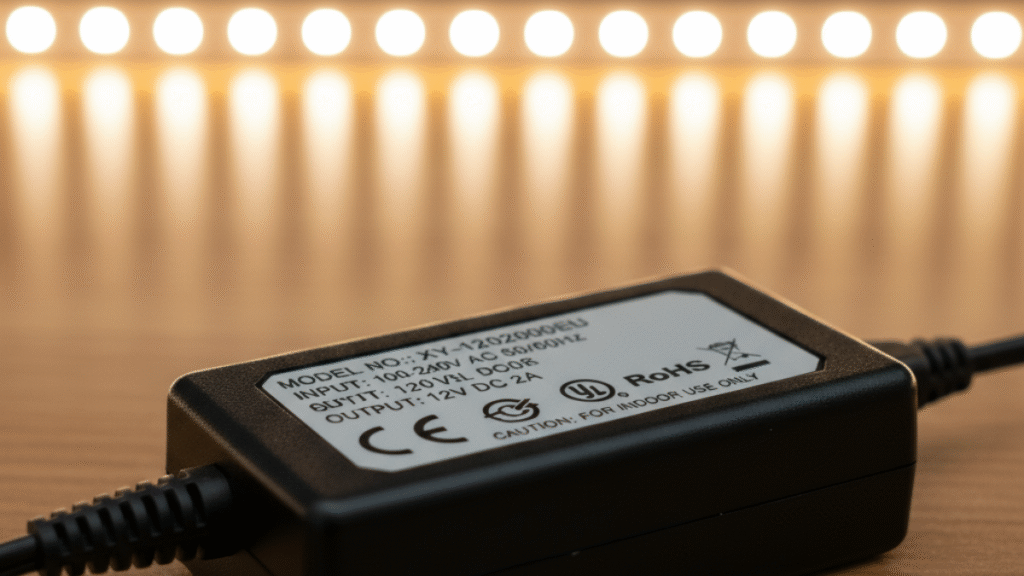

Efficiency and safety are two key indicators of a high-quality LED power adapter. Efficiency refers to how well the adapter converts AC to DC without wasting energy as heat. Standard adapters achieve around 85% efficiency, while premium models exceed 90%. A more efficient adapter consumes less power, generates less heat, and lasts longer. Safety features are equally critical. Modern LED adapters incorporate multiple layers of electronic protection, including over-voltage protection (OVP), over-current protection (OCP), short-circuit protection (SCP), and over-temperature protection (OTP). These circuits automatically cut off power when abnormal conditions occur, preventing damage to both the adapter and the LED strip. When purchasing adapters, users should also check for international safety certifications such as UL, CE, FCC, or RoHS, which guarantee compliance with electrical and environmental standards.

Installation practices play an equally vital role in system reliability. The first step is verifying voltage compatibility and polarity. LED strips typically mark positive (+) and negative (–) terminals clearly; reversing them can prevent illumination or damage components. After confirming polarity, connect the DC output from the adapter to the LED strip input. For small systems, a standard DC barrel connector (2.1 mm or 2.5 mm) is sufficient, but for custom setups, screw terminals or soldered connections provide greater stability. Always ensure the adapter is connected last, after all wiring is complete.

In longer installations, voltage drop becomes a common issue. This occurs because electrical resistance increases over distance, reducing voltage at the far end of the strip. The result is a dimmer light toward the end. Using thicker wires or multiple power feeds can mitigate this problem. In outdoor or humid environments, waterproof adapters rated IP65 or higher should be used. These units feature sealed enclosures that prevent moisture and dust from entering.

Even with careful planning, issues can occur. Flickering lights, uneven brightness, or adapter overheating are common symptoms of mismatched specifications or improper installation. Flickering often indicates that the adapter cannot provide sufficient current, while uneven brightness points to a voltage drop across the strip. If the adapter becomes hot to the touch, it may be overloaded or poorly ventilated. Replacing it with a higher-rated model or ensuring adequate airflow usually resolves the problem. Another frequent issue is complete failure to light up, which is typically caused by reversed polarity or a broken connector. Engineers recommend performing voltage checks with a multimeter to diagnose such cases efficiently.

Advanced lighting systems often require dimming and smart control. The most common dimming method for LED strips is Pulse Width Modulation (PWM). PWM works by rapidly switching the LED on and off at high frequency, adjusting the “on-time” ratio to control brightness without changing voltage. This technique maintains color accuracy and efficiency. Some adapters include built-in dimming capability, while others rely on external dimmers or smart controllers.

Modern LED systems increasingly integrate with wireless control protocols such as WiFi, Zigbee, or Bluetooth. These allow users to adjust brightness and color temperature through smartphone apps or voice commands. In such setups, the adapter acts as the power source while the smart controller manages the signal. Compatibility between these components is crucial for stable operation.

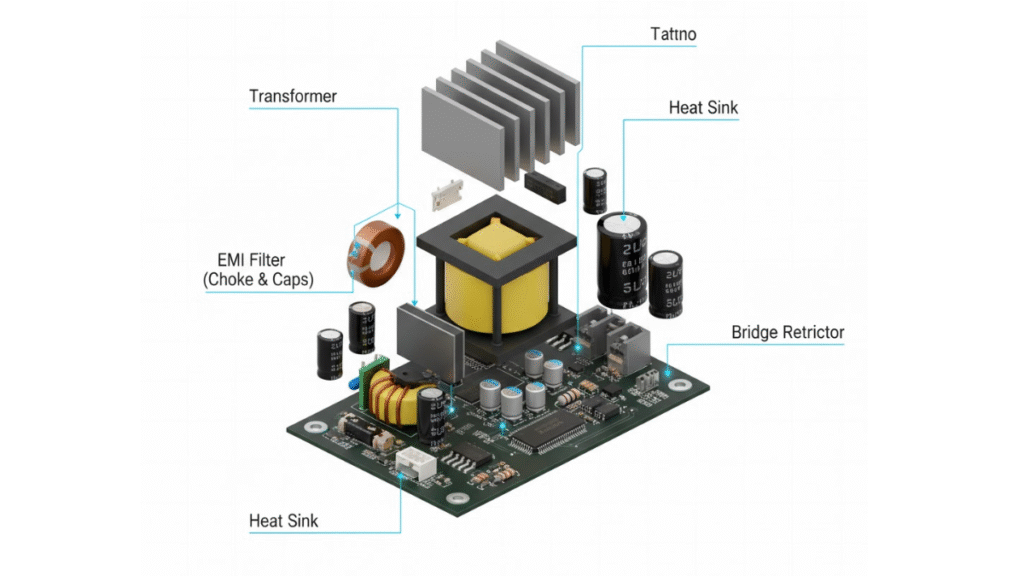

For OEMs and professional lighting designers, several deeper engineering factors determine power supply quality. Heat management is one of the most important. All switching adapters generate heat during operation, and excessive temperature shortens the life of internal components such as electrolytic capacitors. Engineers should ensure adequate ventilation or heat sinks to maintain safe operating temperatures, typically below 60°C ambient.

Electromagnetic interference (EMI) is another consideration. High-frequency switching circuits can generate electrical noise, which may interfere with nearby audio or communication equipment. Effective EMI filters, shielding, and grounding minimize this issue. Reliability over time is also critical in commercial environments. Industrial-grade LED adapters are often designed for lifespans exceeding 50,000 hours, achieved through the use of high-quality capacitors, efficient transformers, and protective coatings.

Selecting the right adapter ultimately comes down to a few essential checks. Always confirm the output voltage (12V or 24V) matches the LED strip specification. Ensure the rated wattage exceeds the total load by at least 20%. Verify the connector type—some strips use DC barrel jacks while others use two-wire terminals. For environments exposed to moisture or dust, select an IP65-rated waterproof model. Finally, check for safety and quality certifications to guarantee compliance with international standards.

In summary, the adapter for LED strip lights is far more than a simple accessory. It is the heart of the lighting system, responsible for ensuring safe operation, consistent brightness, and long-term reliability. Choosing the correct adapter begins with understanding the electrical fundamentals—voltage, current, and power—and continues with selecting the appropriate form factor and protective features for your application. A high-quality, properly rated adapter not only protects the LEDs but also improves energy efficiency and performance. Whether used in decorative home lighting or large commercial installations, the principles remain the same: match the voltage, provide adequate current, allow for safety margins, and prioritize certified components. By applying these engineering best practices, designers and users can achieve stable, efficient, and visually stunning LED lighting that endures for years.