In today’s rapidly evolving technology landscape, power supplies are the backbone of countless devices, from hospital ventilators to point-of-sale terminals. However, not all power supplies are created equal. One of the most crucial distinctions is between medical grade power supplies and commercial power supplies.

Understanding the difference between these two categories is essential for engineers, product designers, procurement teams, and anyone involved in the design and deployment of electronic equipment—especially in healthcare, where safety and reliability can be matters of life and death.

1. Definition and Intended Use

Medical Grade Power Supply

A medical grade power supply is specifically designed and certified to power medical equipment. These power supplies must meet stringent safety and performance standards established by international regulatory bodies, such as:

IEC 60601-1: General requirements for basic safety and essential performance of medical electrical equipment.

ISO 14971: Risk management for medical devices.

EN 60601-1-2: Electromagnetic compatibility (EMC) requirements.

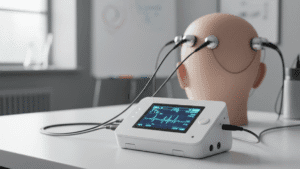

These devices are used in environments where patient contact is possible, including diagnostic devices, monitoring systems, surgical tools, and life-support machines.

Commercial Power Supply

In contrast, commercial power supplies are designed for use in standard industrial or consumer electronic products. They are subject to general electrical safety standards such as:

IEC 60950 (for information technology equipment, now replaced by IEC 62368-1)

FCC Part 15 (EMC regulations for digital devices)

UL or CE safety certifications

They are typically used in office equipment, retail systems, industrial automation, and home electronics.

2. Key Differences

(a) Safety Standards and Leakage Current

The most critical distinction lies in patient safety. Medical power supplies must limit leakage current to avoid electrical shocks that could harm patients, especially those connected to invasive devices.

Medical Grade: Maximum leakage current is typically ≤ 100 µA (microamperes).

Commercial Grade: Can allow leakage up to several milliamperes—acceptable for electronics but unsafe for human contact.

(b) Isolation and Reinforced Insulation

To protect patients and caregivers, medical power supplies are required to have two means of patient protection (2 x MOPP). This involves reinforced insulation and a minimum isolation voltage of 4000 VAC.

Commercial units often use only 1 x MOPP or 1 x MOOP (means of operator protection), with lower isolation requirements.

(c) Electromagnetic Compatibility (EMC)

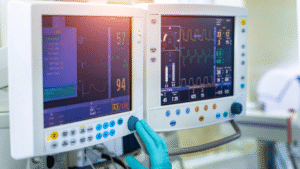

Hospitals have sensitive equipment operating in close proximity—MRI machines, infusion pumps, ECG monitors. Medical power supplies must therefore adhere to stricter EMC standards to minimize electromagnetic interference (EMI).

Commercial power supplies are not subjected to the same level of testing, as interference in consumer applications does not pose the same risk level.

(d) Reliability and Operating Conditions

Medical devices often operate continuously and must maintain performance over time with minimal failure. Medical power supplies are engineered for high MTBF (mean time between failure), continuous duty cycles, and wide temperature ranges.

Commercial supplies are not always built for 24/7 operation and may degrade faster in demanding conditions.

(e) Certification Process

Getting a medical power supply certified is a rigorous, time-consuming, and expensive process. Manufacturers must provide detailed documentation, testing data, and undergo factory audits. This ensures traceability, quality control, and ongoing compliance.

In contrast, commercial power supplies have a more straightforward path to market, focusing on general product safety and performance.

3. Use Cases and Risk Considerations

| Use Case | Recommended Supply Type |

| ICU ventilators | Medical grade |

| Cosmetic laser equipment | Medical grade |

| Barcode scanner in retail store | Commercial grade |

| MRI-compatible monitoring system | Medical grade |

| Cash register or kiosk system | Commercial grade |

| Home-use TENS (electrotherapy) unit | Medical grade |

Using a commercial power supply in a medical application—especially one involving patient contact—can result in regulatory non-compliance, device failure, or even patient injury. This not only endangers lives but also exposes manufacturers to legal liability, product recalls, and brand damage.

4. Why Not Just Use Medical Grade Power Supplies for Everything?

While medical power supplies offer enhanced safety and reliability, they also come at a higher cost, often 2–3 times more than their commercial counterparts. Additionally, they may involve longer lead times due to certification and production processes.

Therefore, it’s not economically feasible to use medical grade supplies in non-critical or non-medical devices. Proper selection based on application risk, environment, and compliance requirements is crucial.

5. Future Trends: Intelligence and Efficiency

As medical devices become smarter and more connected, power supplies are evolving too. New-generation medical power supplies incorporate features such as:

Digital control and monitoring (PMBus, I2C)

High efficiency (up to 94%) for reduced heat generation

Low-noise designs for imaging and diagnostic applications

Modular and configurable architectures for space-constrained devices

The integration of AI, remote diagnostics, and wireless power transfer is also starting to influence design trends in both commercial and medical-grade power systems.

Conclusion: Choose the Right Power Supply for the Right Purpose

When designing or sourcing components for electronic systems, understanding the differences between medical grade and commercial power supplies is essential.

Medical grade is your only safe and compliant choice for life-critical or patient-connected equipment.

Commercial grade is a cost-effective, reliable option for general-purpose electronics and consumer applications.

Compromising on power supply quality or certification—especially in medical environments—is not an option.

Choose Quankang Medical Grade Power Supplies for Trusted Reliability

At Quankang, we understand the critical role that power supplies play in healthcare. Our medical grade power supplies are rigorously designed and certified to meet IEC 60601-1 and EN 60601-1-2 standards, offering:

Low leakage current for patient safety

2 x MOPP isolation for regulatory compliance

High MTBF and 24/7 operation capability

Compact, fanless, and energy-efficient designs

Whether you’re developing diagnostic instruments, therapeutic devices, or patient monitoring systems, Quankang medical power supplies deliver the reliability, safety, and performance that your applications demand.