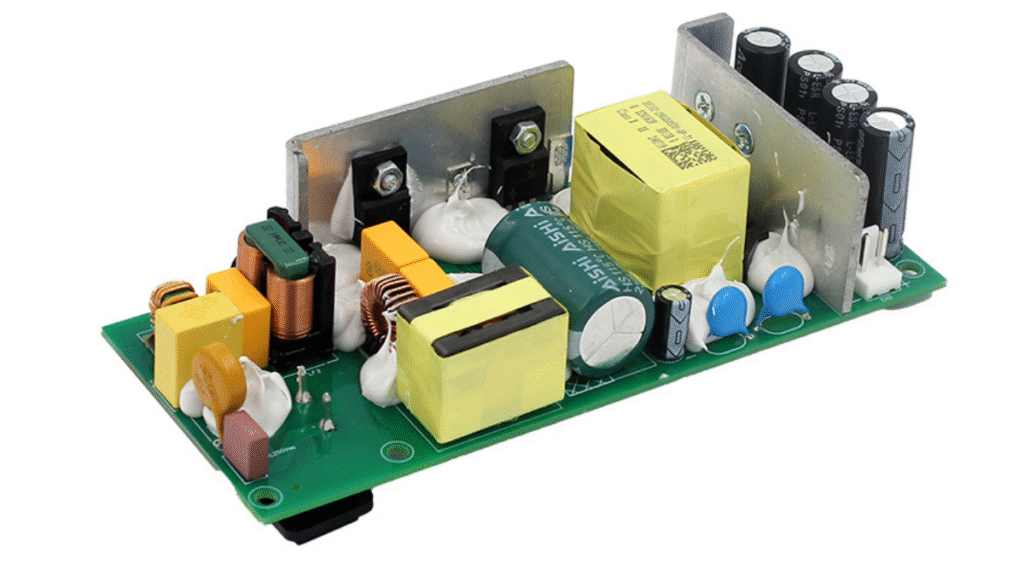

If it’s sometimes hard for you to choose a suitable medical power supply to put outside the device, then you may try an open-frame power supply.

What is an open-frame power supply?

Open-frame power supply refers to a power module without a closed casing. It usually only contains a PCB board and components, which are exposed to the outside and need to be installed inside a device or in a system with a casing. It has a smaller size, good heat dissipation, and is easy to integrate.

Core Advantages of Open-Frame Power Supplies

There are four main advantages of an open-frame power supply.

It has outstanding thermal performance, with an exposed structure that allows air to flow freely. Some models in Quankang are equipped with a fan that gives a more powerful thermal control, making them ideal for high-power or continuous-operation devices.

In some devices, like infusion pumps or oxygen concentrators, they handle heat far more efficiently than enclosed types.

Open frame power supplies are generally small and can be easily integrated into the device. The open layout allows easy embedding into system interiors, saving both space and assembly cost.

From a cost-efficiency standpoint, removing the metal casing not only reduces manufacturing expenses but also gives engineers more design freedom and simplifies later maintenance or upgrades.

The open-frame structure allows engineers to more easily perform circuit-level adjustments, such as modifying the output voltage range, adding protection circuits, and replacing specific components to meet safety or EMC requirements. This is impossible with enclosed adapters.

In medical equipment, if customers need to pass IEC-60601-1 certification or modify their products, they only need to adjust the parameters or layout on the open-frame module without having to redo the entire machine structure, thereby significantly reducing the time cost of certification and production.

These benefits explain why open-frame power supplies are now widely adopted across industrial control systems, medical devices, and communication equipment, where compact, reliable, and cool-running power sources are critical.

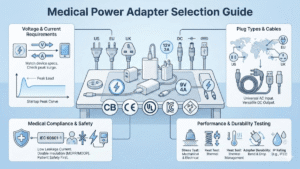

Choosing the Right Open-Frame Power Supply: What You Can’t Ignore

Open-frame power supplies are built for internal integration. Match power not only to rated load but also to startup current and peak demand — insufficient margin can cause overheating or voltage sag over time.

Their open structure improves heat dissipation, but only if the device provides proper airflow. Plan heat paths, fan positions, and airflow direction to avoid hotspots, especially in medical equipment.

Always choose UL/CE/IEC 60601-1/2×MOPP certified models. Because the boards are exposed, ensure safe creepage distance, solid grounding, and proper shielding to prevent electric shock. Contact us to get a certified open-frame power supply solution.

Open-frame designs simplify servicing, but dust and humidity protection remain critical. Prefer units with conformal coating or modular replaceable parts for long-term reliability.

Conclusion: Compact Doesn’t Mean Compromised

Open-frame power supplies are ideal for devices requiring compact integration and long-term stable operation.

But “exposed” doesn’t necessarily mean “simple”—proper design and compliance certifications are equally crucial in medical and industrial applications.

Choosing a reliable manufacturer means buying more than just a board; you’re buying a comprehensive suite of technical support and safety assurance.