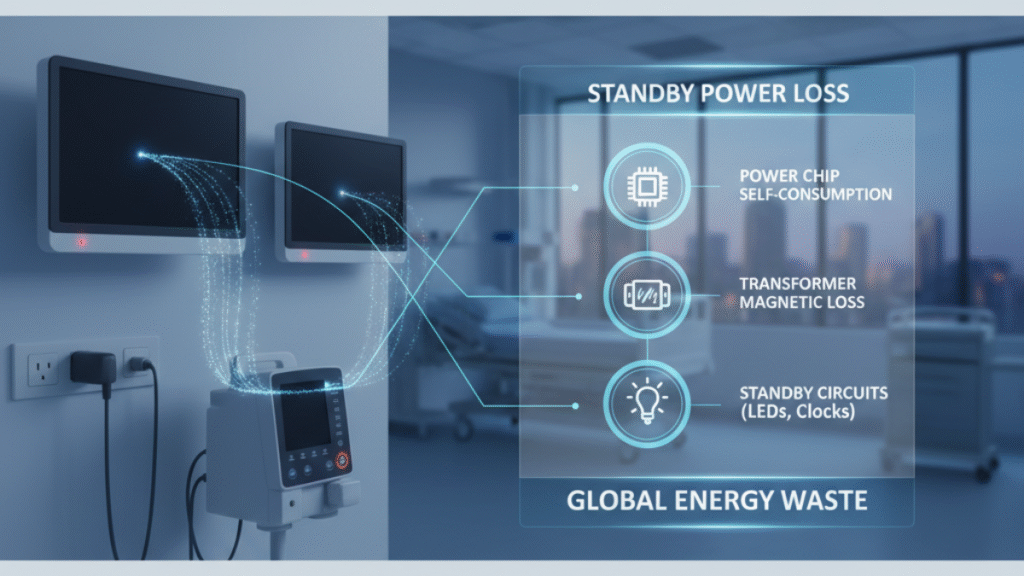

At night, the devices in hospitals, like monitors, infusion pumps, and oxygen concentrators, most of them will be turned off to save power. Of course, we would think so. The truth is, even when the devices are turned off, the power supplies are still consuming power

Where does standby power consumption come from?

Standby power consumption, which means the power consumption when the device is plugged in but not operating.

And you may ask, “the device doesn’t even work!Where did the power go?”

The answer is that there are four types of standby power consumption.Self-consumption of the main power chip to maintain low-power operation,capacitor leakage in the EMI filter circuit,transformer magnetic loss and switch leakage current and always-on circuits such as indicator lights and detection circuits.

You may think that the consumption must be low, as the devices are turned off.These tiny losses are not noticeable on a single device, but they will be infinitely magnified when they are used by hundreds or thousands of devices in a hospital.

Why are medical devices more demanding on standby power consumption?

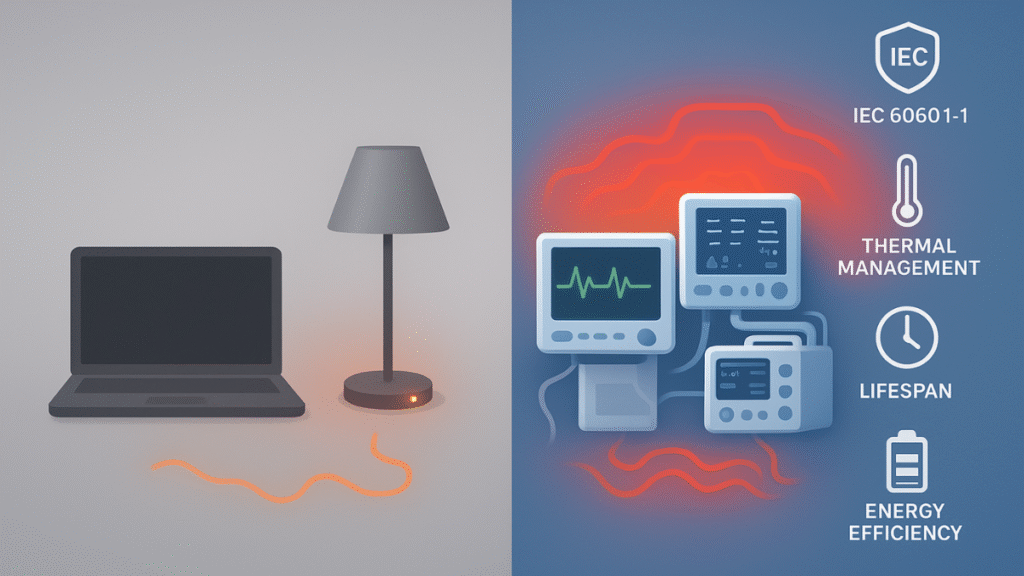

Just as I mentioned before, in a hospital, there are hundreds of thousands of medical devices consuming the power.And even though they are turned off, the standby power is also a waste,saving energy is not only environmentally friendly but also the matter of thermal management and devices lifespan.

We know that all medical devices must meet the requirement of IEC 60601-1,which requires that power supplies maintain electrical safety and low leakage current even in sleep or standby modes.

What’s more, it may cause a lot of problems if the standby power consumption is always too high.The power supply with high standby power consumption will produce excessive heat and reduce the lifespan of the components,lead to the waste of power when massive operation,increased risk of electrical interference during standby mode.

As standby power consumption will cause that many problems,let’s see how it was solved.

How do engineers reduce standby power consumption?

The engineers in Quankang_ _have put a lot of effort into reducing the standby power consumption,they replace the controlling chip to let the adapter as well as the devices sleep when standby, use Quasi-Resonant(QR) or valley switching technology to reduce the power loss when switching.

For most of our certificated models, we add automatic power-off logic or intelligent power management IC to allow the power adapter to cut down the energy when devices are off or enter a deep standby mode.

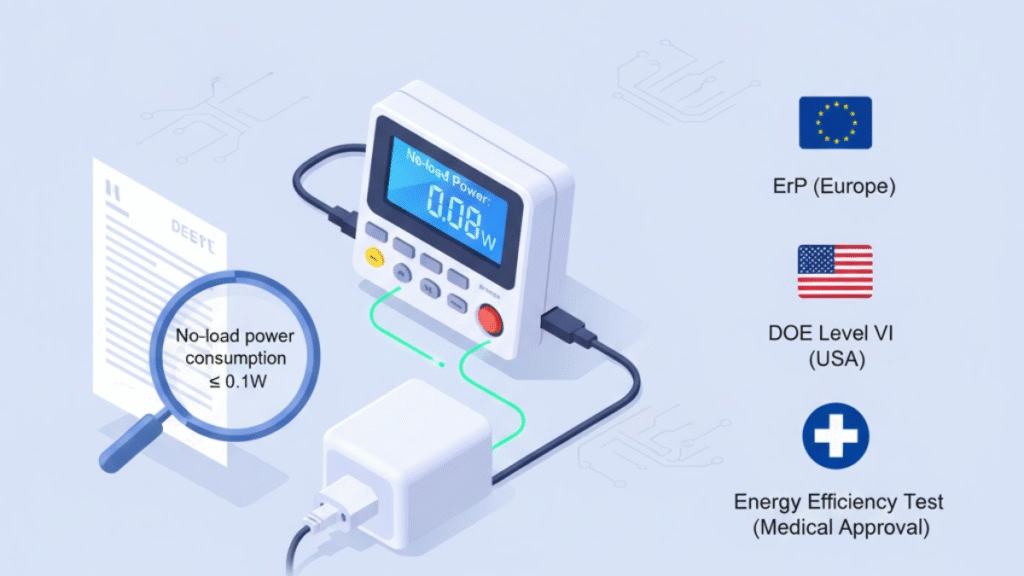

With the methods above, the medical-grade power supplies of Quankang are able to consume less than 0.1 Watt at standby,so as to reduce the heat and risk of aging in the massive operation of medical devices.

How to determine whether the standby power consumption of the power supply meets the standard

After all the introduction, I bet you may want to know whether the adapters you have could meet the standard,here is the methods:

Firstly,search the no-load power consumption specification in the datasheet of your adapter.

Secondly, use the power meter to check if the no-load power consumption can meet the regulation of different countries,for example Erp standard in Europe,DOE level VI in America. By the way,when medical equipment is submitted for approval, this data is often one of the important indicators for whether it can pass the energy efficiency test.

Conclusion

Energy saving is more than just electricity saving.

Controlling the standby power consumption is not only for saving energy,but also ensuring the stability and lifespan of medical-grade power supply as well as the devices.And that’ s because for medical devices,each watt matters,each watt has the possibility to save lives.

Contact us to learn how to make your medical power supply more energy-efficient and robust without sacrificing performance.