In LED lighting systems, the driver power supply is the core component determining luminous efficacy and lifespan. External LED drivers, with their modular design, excellent heat dissipation, and convenient maintenance, have become the mainstream choice for table lamps, spotlights, and engineering lighting. This article will delve into the design considerations of external LED drivers from four dimensions: structural design, heat dissipation optimization, electrical isolation, and safety standards.

I. Scientific Heat Dissipation Design for More Stable Driving

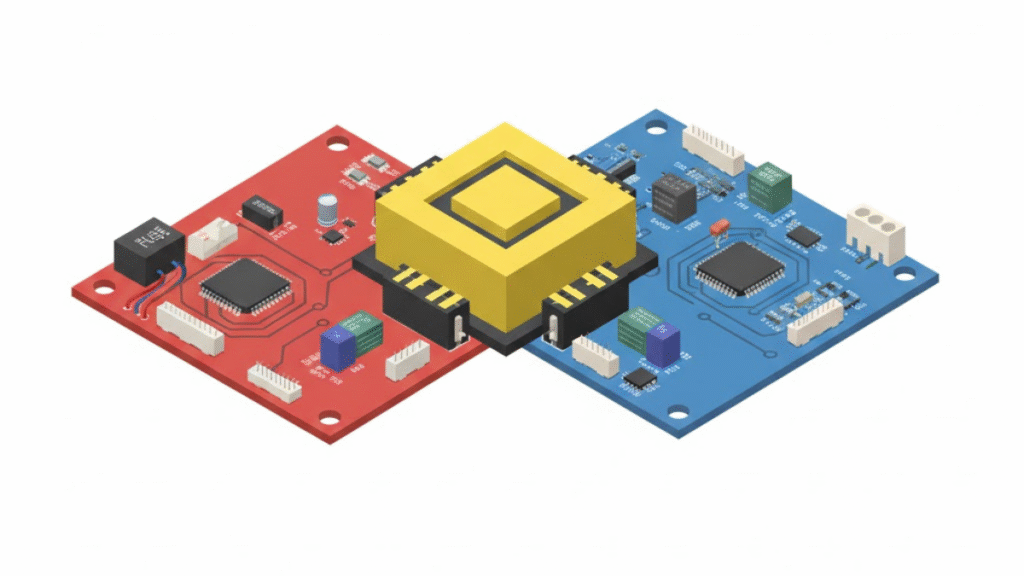

Heat dissipation performance directly affects the lifespan and stability of the LED driver power supply. Components such as transformers, MOSFETs, rectifier bridges, and filter capacitors in the power module generate heat during operation. An inadequate heat dissipation design can easily lead to excessive temperature rise, shortened lifespan, or even failure.

In an external driver structure, components should be rationally arranged, and airflow channels optimized to avoid the concentrated stacking of high-temperature components. For medium-to-high power applications, aluminum alloy housings or thermally conductive silicone are recommended to improve thermal conductivity. Meanwhile, for different usage environments (such as indoor desk lamps and outdoor lighting fixtures), a sufficient temperature rise margin must be included in the design, and high-temperature aging and extreme testing must be conducted to ensure product reliability during long-term operation.

II. High-Efficiency Design: Dual Enhancement of Energy Saving and User Experience

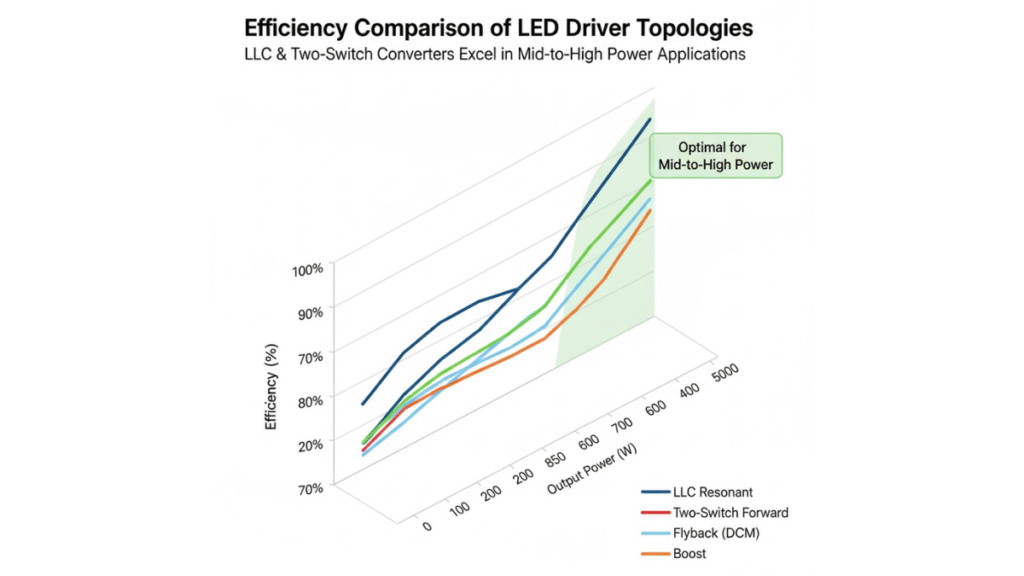

High-efficiency LED drivers not only mean lower energy consumption but also significantly reduced heat generation, further extending product lifespan. Common topologies include flyback, buck, and LLC resonant.

Low-power desk lamps typically use flyback structures, which are simple, low-cost, and highly stable.

Medium-to-high power drivers tend to use LLC or dual-transistor forward converters to achieve higher conversion efficiency and lower EMI.

In component selection, priority should be given to low-loss magnetic cores, low-ESR capacitors, and high-efficiency MOSFETs to improve overall performance. During the design process, efficiency and cost must be balanced to ensure the driver meets performance requirements while remaining competitive in the market.

III. Electrical Isolation Design: Safety is the Bottom Line

As a device directly connected to mains power, the LED driver must be absolutely safe in terms of electrical design. The transformer is the core of the isolation system. During design, it is essential to ensure that the creepage distance and clearance between the primary and secondary windings meet standards (generally ≥4mm), and the high and low voltage areas must be clearly distinguished in the PCB layout.

Furthermore, the input end should be equipped with surge suppression (MOV, NTC) and other protective components to resist lightning strikes and power grid interference; the output end should have short-circuit, overcurrent, and overvoltage protection to prevent damage to the LED light source or the power supply itself under abnormal conditions. Through a multi-layered protection design, user safety can be maximized.

IV. Standards and Certifications: Key to Market Entry

Whether it’s lighting products exported to Europe or desk lamp drivers for the domestic market, compliance certification is a necessary condition for product launch.

CE Certification: Covers both LVD (Low Voltage Direction) and EMC (Electromagnetic Compatibility) to ensure safety and anti-interference performance.

CCC Certification: A mandatory safety certification in China, testing items including insulation, withstand voltage, temperature rise, structure, and marking.

UL, PSE, KC, and other regional certifications: For different market standards, structural and electrical margins should be reserved in the initial design phase to avoid repeated testing due to later modifications.

Following these standards is not only a regulatory requirement but also reflects a company’s emphasis on product quality and user safety.

V. Conclusion: Making Light Safer and More Efficient

An excellent external LED driver not only “drives light” but also “protects safety.” Heat dissipation design ensures lifespan, efficiency optimization enhances the user experience, and safety standards establish the bottom line for quality.

In future lighting trends, LED drivers will evolve towards higher power density, intelligent dimming, and lower standby power consumption. For every engineer and brand manufacturer, adhering to technical specifications, optimizing structural design, and focusing on certification compliance are key to creating high-quality LED driver products.