We all know that for medical devices, safety standards and insulation are always the first concept that comes to mind. Safety standards protect you when you are using medical devices, and insulation prevents you from being electrocuted.

The Concept of Safety and Its Compliance Standards

When we talk about safety, we have to first mention hazards. Electric shock, fire and heat-related hazards, mechanical hazards, radiation, and chemical hazards are all hazards. So, what is the purpose of safety regulations?

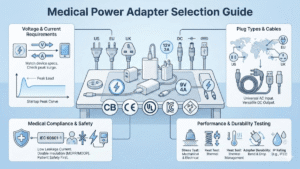

The purpose of safety regulations is to reduce the hazards above. Usually, a higher-quality medical power adapter will have a higher standard of safety regulation.

The safety regulation standards are divided into general standards and product standards.

IEC 60664-1 is a general basic standard for insulation coordination of low-voltage equipment, providing a technical basis for various product safety standards. And on this basis, different types of equipment will have their own product standards, such as medical equipment following IEC 60601-1. These product standards will impose stricter requirements on insulation, protection, and leakage indicators based on specific usage risks.

Insulation protection

The key consideration in power supply design is electric shock protection. This is generally achieved through grounding and insulation.

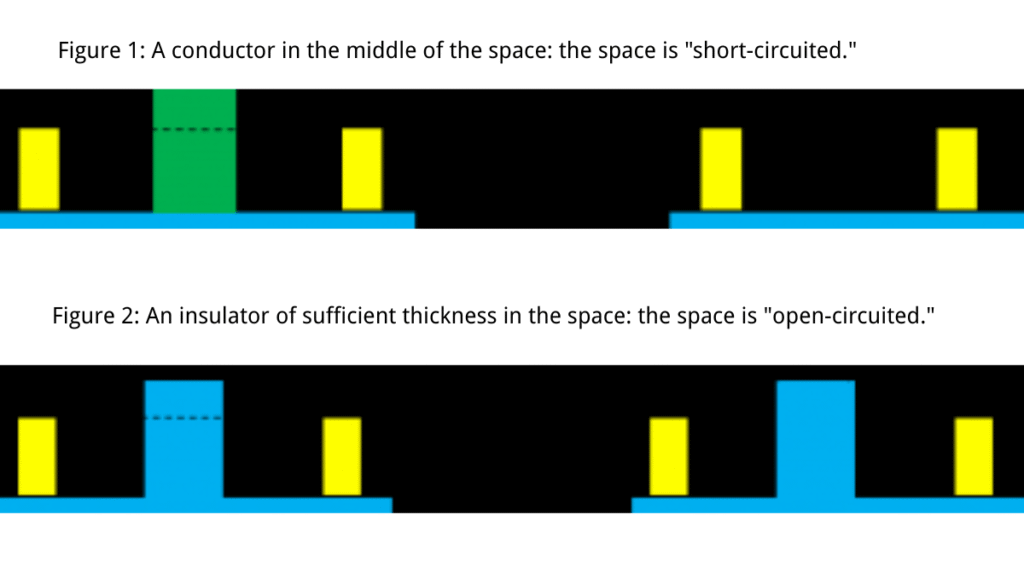

The insulation protection standards are mainly applicable to protection scenarios using air as the medium, and do not involve liquids, special gases, or compressed air. Protection is achieved by maintaining a safe electrical gap between the human body and hazardous live parts. This measure only applies to conductor components, and the insulator itself does not require additional protection.

Common insulation materials include glass, ceramics, mica, plastic, resin, paint, rubber, wood, and paper, which need to maintain sufficient dielectric and mechanical strength after wet heat testing. Materials with strong moisture absorption or containing asbestos are prohibited from being used for insulation purposes due to their tendency to reduce insulation performance.

Insulation Protection Achieved Through Clearance and Creepage Design

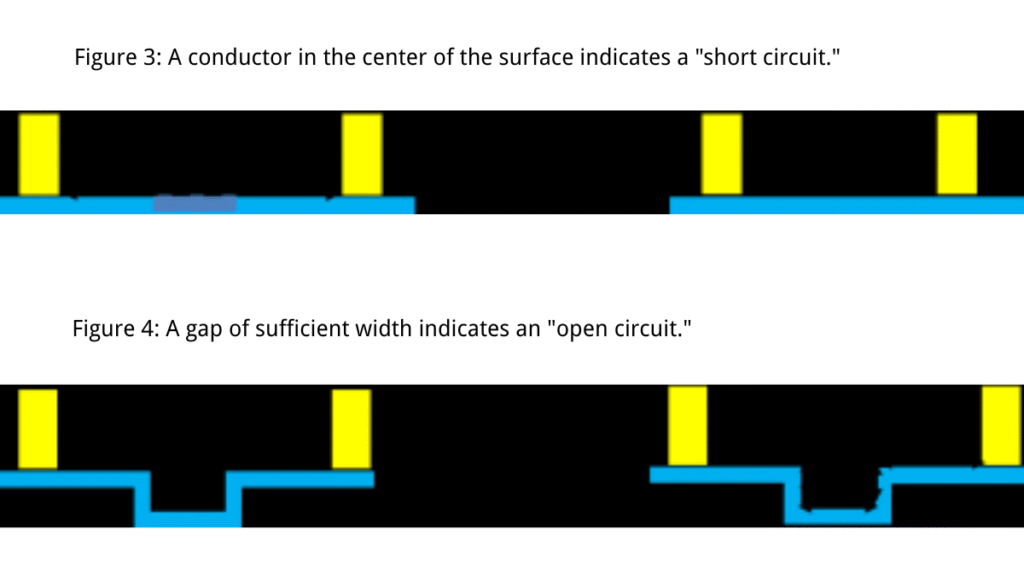

What is electrical clearance? First, let’s look at the definition: the shortest distance in the geometric space between two conductors (or between a conductor and a protective surface) in a vacuum with uniform electrical properties.

Then let’s look at creepage distance.

Creepage distance is defined as the shortest distance along the surface of an insulator with uniform electrical properties between two conductors (or between a conductor and a protective surface).

From Creepage to Care: How Safety Distances Shape Medical Power Adapters

All we mentioned above is about insulation in industry-grade devices, but for medical devices, the requirement is far more rigorous. For IEC 60601-1 compliance, taking the common 2×MOPP(Means of Patient Protection) insulation type as an example, the distance of creepage and clearance must be higher than 8mm to meet the requirement, while 2.5mm is enough for industry grade, and their operation environment is just the same.

The difference in creepage and clearance between medical and industry is because some medical devices will directly contact the human body or enter body tissues, and for industry, the safe insulation standard is 1×MOOP(Means of Operator Protection).

Double Insulation and Patient Protection

In medical power supply design, a Class II structure or reinforced insulation is the core means to ensure safe operation without grounding.

Through double or thick insulation, even without a ground wire, current cannot flow directly to the human body, thereby reducing the risk of electric shock. At the same time, insulation design directly affects the size of leakage current.

Medical equipment has extremely low leakage current requirements on the patient side – usually only tens of microamperes (μA) to ensure that sensitive parts of the heart or nerves are not harmed.

In typical applications, circuits directly in contact with the patient, such as monitors, electrocardiogram (ECG) devices, and infusion pumps, must undergo rigorous insulation and testing to ensure that leakage current remains within safe limits, even under high humidity and continuous use. This design ensures that medical power supplies not only comply with the IEC 60601-1 standard but also provide reliable patient safety.

From Insulation Design to a Reliable Power Solution

Insulation is not only a standard, but also a guarantee for the stable operation of medical equipment. Quankang has put a lot of effort into ensuring insulation safety; each of our products can meet the standard of 2×MOPP, and each unit undergoes insulation testing to ensure safety.

From design to testing, every layer of insulation, every safety margin, and every certification represents our promise that patients and caregivers can use our power supplies with complete confidence.

At Quankang, safety is not just built into our adapters — it’s built into our philosophy.