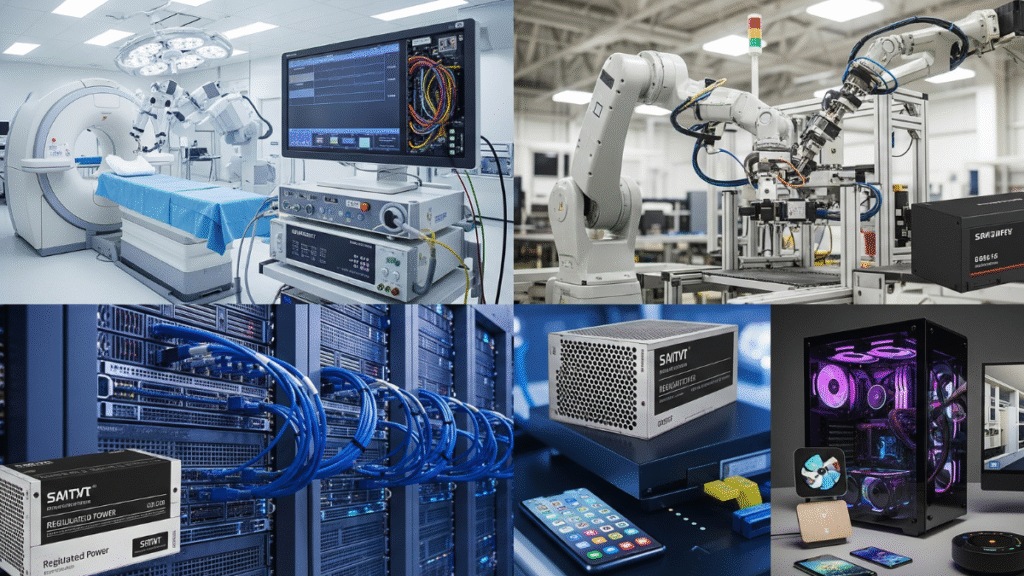

Power supplies are critical components across many sectors—from factory automation to patient monitoring. While they may seem similar in function, medical power supplies and industrial power supplies differ significantly in design, safety requirements, certifications, and application demands. These differences are not just technical—they have real-world implications for regulatory approval, product reliability, and user safety.

1. Fundamental Purpose and Use Cases

Medical Power Supply

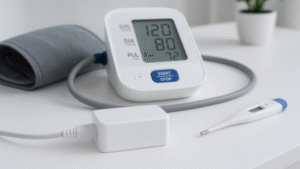

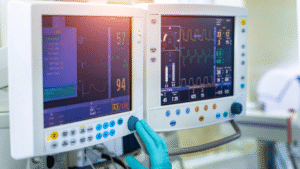

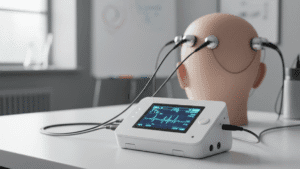

Designed for use in healthcare equipment where patient safety is paramount. Applications include:

Diagnostic devices (e.g., ultrasound, ECG, MRI)

Life-support systems (e.g., ventilators, dialysis machines)

Therapeutic tools (e.g., surgical lasers, infusion pumps)

Home medical devices (e.g., CPAP machines, breast pumps)

Industrial Power Supply

Built for machinery and automation in non-medical environments, including:

Robotics

Manufacturing lines

Instrumentation systems

PLCs and SCADA systems

Harsh field installations

Though both types convert AC to DC or regulate power, medical supplies must meet stringent human safety standards, while industrial supplies prioritize performance under mechanical and electrical stress.

2. Safety Standards and Regulatory Compliance

Medical Power Supply

Must comply with IEC 60601-1 (currently Edition 3.2) which governs:

Electrical and mechanical safety

Patient protection (MOPP)

Ultra-low leakage currents

Risk management and usability

Other applicable standards:

IEC 60601-1-2 (EMC)

IEC 60601-1-11 (Home-use devices)

UL/CSA 60601, EN 60601 (regional versions)

Without this compliance, a medical device cannot receive FDA, CE, or NMPA approval.

Industrial Power Supply

Typically adheres to:

IEC 61010-1 (measurement/control equipment)

IEC 62368-1 (replacing 60950-1 for IT and AV equipment)

EN 60204-1 (safety of machinery)

UL 508, CE (for industrial control)

Industrial standards allow higher leakage current and less stringent insulation because human contact is less direct and frequent.

3. Leakage Current Requirements

Leakage current is a key differentiator:

| Category | Maximum Allowable Leakage Current |

| Medical (CF Type) | ≤ 10 µA (Normal), ≤ 50 µA (Fault) |

| Medical (BF Type) | ≤ 100 µA |

| Industrial Equipment | Typically < 3.5 mA |

Medical power supplies must maintain extremely low leakage current to prevent cardiac interference or electric shock, especially in devices with electrodes or invasive contact.

Industrial devices, on the other hand, prioritize EMI performance and energy efficiency, accepting higher leakage for better noise suppression.

4. Isolation and Protection Requirements

Medical

Requires 2 x MOPP (Means of Patient Protection)

Minimum 8mm creepage distance

4,000 VAC isolation between input and output

Double/reinforced insulation

High-grade Y capacitors to minimize leakage

Industrial

Typically meets 1 x MOOP (Means of Operator Protection)

2.5–5mm creepage

1,500–3,000 VAC isolation

Can operate safely without reinforced insulation

Medical-grade insulation must be fail-safe and fault-tolerant, while industrial applications accept moderate insulation trade-offs for cost or size.

5. Environmental and Mechanical Tolerances

Industrial

Designed for harsh environments: wide temperature (-40°C to 85°C), vibration, dust, moisture.

Often includes ruggedized enclosures (IP65+).

Enhanced cooling mechanisms for continuous operation under load.

Medical

Typically operates in controlled environments (hospitals, clinics, homes).

Must meet patient-touch safety standards even in portable form factors.

Growing need for IP-rated, compact, and fanless designs in home healthcare.

Industrial supplies often prioritize durability and electromagnetic robustness, while medical units prioritize quiet operation, hygiene, and safety.

6. Certifications and Testing

Medical power supplies undergo:

Type testing for IEC 60601-1

Risk management assessments under ISO 14971

Biocompatibility checks for patient contact

Pre-compliance EMC testing (60601-1-2)

Full documentation for CE, FDA, and CB Scheme

Industrial power supplies go through:

Type tests for thermal, EMC, and surge protection

Optional functional safety certifications (e.g., SIL)

Less extensive risk/human safety assessments

Medical approvals are often costlier and slower, requiring longer product development cycles.

7. Cost and Complexity

Due to their strict compliance requirements, medical power supplies are generally more expensive than industrial ones with similar wattage and form factor.

| Factor | Medical Power Supply | Industrial Power Supply |

| Compliance burden | Very high (safety, EMC) | Moderate to high |

| Cost per unit | Higher due to certification | Lower |

| Development time | Longer | Shorter |

| Customization flexibility | Limited (due to re-certification) | More flexible |

However, the cost is justified in medical applications because failure can result in life-threatening consequences and legal liability.

8. Supply Chain and Support Differences

Medical-grade suppliers typically offer:

ISO 13485-certified production

100% burn-in and leakage testing

Long product life cycles (5–10+ years)

Document control and change notifications

Integration support for certification

Industrial suppliers focus on:

Supply chain flexibility

High-volume availability

Broad voltage and form factor selection

Shorter lead times

Selecting a trusted medical power supply partner, like Quankang, ensures access to fully certified IEC 60601-1 solutions with ultra-low leakage, robust documentation, and long-term availability.

9. When to Use a Medical Power Supply

You should always use a medical power supply when:

The device comes in direct or indirect contact with patients

The application involves home healthcare

The equipment will undergo regulatory approval (CE/FDA/NMPA)

Patient safety could be compromised by any electrical failure

Examples: ECG monitors, defibrillators, infusion pumps, CPAP devices, cosmetic lasers, UV therapy instruments, or electric breast pumps.

10. Conclusion: Safety vs Performance—A Strategic Choice

While industrial and medical power supplies both deliver electrical energy, their roles and responsibilities are vastly different. Medical supplies must deliver electrical performance with zero compromise on safety, while industrial supplies emphasize efficiency, ruggedness, and cost control.

Understanding the difference allows engineers and decision-makers to select the right power supply for the right job—one that not only meets electrical demands but also aligns with regulatory, operational, and human safety needs.

If your device is used in a healthcare setting or touches a patient in any way, there’s no shortcut: IEC 60601-1-compliant, medical-grade power supplies are a must.

Quankang offers a complete line of certified medical AC-DC adapters and power modules, designed to meet strict IEC 60601-1, 2 x MOPP, ultra-low leakage current, and home-care IEC 60601-1-11 requirements. Their solutions are ideal for ventilators, breast pumps, therapy devices, and portable medical instruments—ensuring that every device powered is safe, compliant, and ready for global deployment.